Green Products and Innovation

Sustainable Production

USI actively introduces smart manufacturing through the automated lights-out factory project to streamline production quality and efficiency, meet customer demand, and continue optimization of design, production, and energy efficiency through the Continuous Improvement Program.

Smart Manufacturing

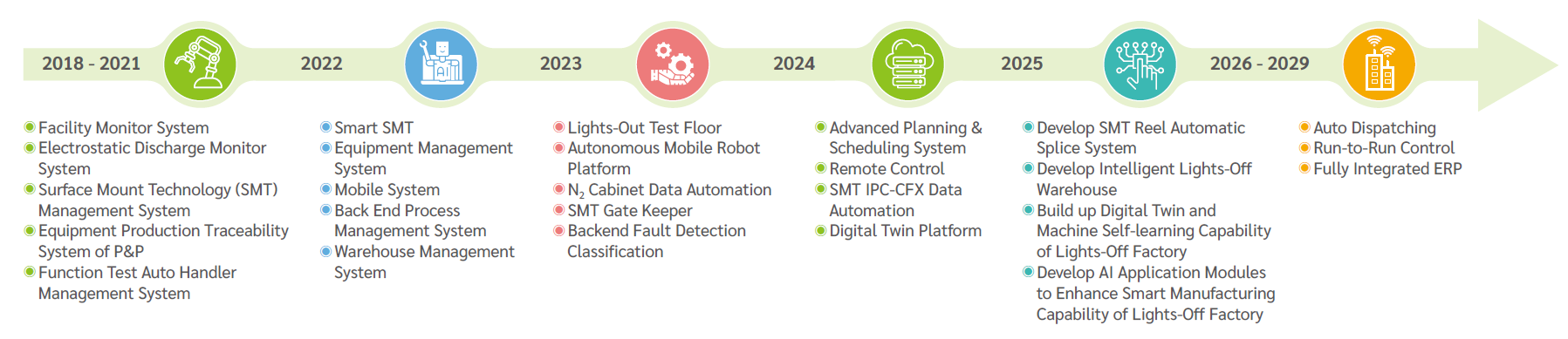

USI's Smart Manufacturing Program has adopted the concept of Industrial Internet of Things (IIoT) and plans the development of the Industry 4.0 Smart Manufacturing Program in line with the electronic manufacturing industry, and this is called the 5-Star Industry 4.0 Smart Manufacturing.

In 2024, we successfully introduced 68 automated manufacturing projects, saving a total of CNY 310.38 million in labor costs, with an average of 3.07-Star Facilities, total 3 of Lights-Out product line, and 6 out of 54 application modules are AI application modules. The Company plans to develop 6 common platforms in 2025, and upgrade all facilities with implementation of Industry 4.0 to 3-Star or 4-Star factories in 2029, such that the average class of facilities will reach 4.26-Star and develop 18 AI application modules. USI aims to implement Lights-Out Factory in all facilities worldwide, at least building one fully automated smart manufacturing production in each facility.

Lights-Out Factory Roadmap

We deployment the AOI+AI defect inspection system was implemented at the Jinqiao Facility in 2023 and at the Zhangjiang Facility in 2024. Utilizing AI deep learning models, the system can quickly identify over 85% of defect types. Compared to traditional inspection methods relying on human visual rechecks, it improves efficiency by more than 60%.

In addition to the AOI+AI technology, we have introduced an automated inspection station (FCT station), which is combined with AI to further enhance production efficiency technology. In the FCT station, the introduction of AI has significantly optimized the test process, reducing the original single test time by about 50%, reducing production energy consumption and false alarm problems in the laser inspection system, and significantly reduces the risk of human factors affecting product quality.

Continuous Improvement Program (CIP)

Continuous Improvement Program (CIP) proposes improvement plans for the productivity, process, quality, efficiency, equipment, software, hardware, energy conservation and CO2 emission reduction, automation, safety, digital innovation, and have cost saving benefits. Its purposes are as follows:

- Build a platform to realize ideas and approve employees' endeavors and awards

- Encourage employees devoting to continuous improvement

- Enhance teamwork and enterprise competitiveness

After the 2024 annual performance examined and approved by Corporate Review Committee (CRC), the actual tangible cost saving was CNY 120.26 million. The saving cost accounted for 0.26% of revenue and a total of CNY 1.07 million has been reward employees for their commitment to continuous improvement.

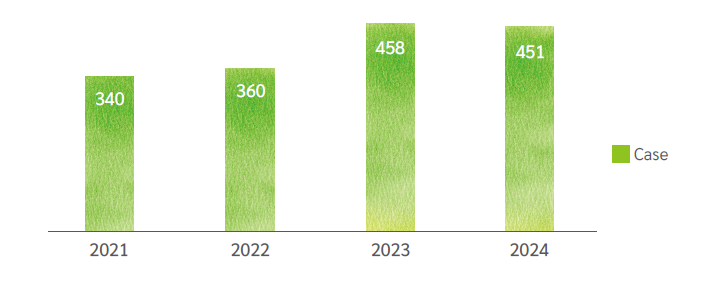

Proposed New Cases of CIP

In response to the issue of climate change, we have included Energy Saving and Carbon Reduction in the rating system and the type of key project to promote relevant green proposals. In 2024, there were 1 digitalization innovation project and 3 energy-saving and carbon reduction projects receiving awards, the total carbon reduction amount 2,543 metric tonnes.

| Facility | Rank | Project Name | Key Project Benefit |

|---|---|---|---|

| Kunshan | Gold | Digital Research & Development of Three Environmental Monitoring Devices (digitalization innovation) |

We independently developed online monitoring systems for equipment grounding, electrostatic discharge wrist strap monitoring, and dust particle monitoring. By integrating LORA wireless communication for digital data collection and displaying results through digital dashboards, we have reduced the need for on-site measurements and manual recording by personnel. This enhances control capabilities and improves customer satisfaction, with cumulative savings of CNY 0.80 million. |

| Kunshan | Silver | Chiller Smart Control System Implementation (energy-saving and carbon reduction) |

We have implemented intelligent control logic for our chiller systems to replace manual fixed-state controls. The system automatically adjusts equipment parameters based on end-point cooling demand and changes in outdoor temperature and humidity, enabling a fully automated and optimized system management mode, saving 1,396 MWh of electricity annually, saving 13,563 metric tonnes of water and reducing carbon emissions by 1,093 metric tonnes, with cumulative savings of CNY 0.78 million. |

| Huizhou | Silver | Photovoltaic Power Generation System (energy-saving and carbon reduction) |

A distributed solar power generation system, led and implemented by USI, was installed on rooftop areas and parking canopies. This setup helps reduce floor slab temperatures, thereby improving the working and production environment for offices and facilities located on the upper floors, saving 1,830 MWh of electricity annually and reducing carbon emissions by 1,413 metric tonnes, with cumulative savings of CNY 0.93 million. |

| Jinqiao | Bronze | Air Conditioning Condensate Water from The Production Building is Recycled to The Cooling Tower (energy-saving and carbon reduction) |

The condensate piping in the production building was modified so that condensate from each floor is collected into a condensate tank, then pressurized and supplied to the cooling towers in the utility building, eliminating the need for wastewater treatment, saving 89 MWh of electricity annually and reducing carbon emissions by 37 metric tonnes, with cumulative savings of CNY 0.32 million. |