- Media Highlights

- 07/12/2021

USI: Transform Labor-intensive Production into High-productivity Intelligent Manufacturing

——Interview 3 of "Automation Giants Embrace the Era of Industrial Internet"

[Application of Electronic Technique - Top Interview] 2021.07.12

Reporter | Wei Xiaowei

[Editor's Note]

The "14th Five-year Plan" period is a key stage for the industrial Internet, together with 5G, big data, artificial intelligence, and other new-generation information technologies, to accelerate the transformation and upgrading of the manufacturing industry. The industrial Internet is reshaping the ecology of the manufacturing industry, and makes everything look new and fresh. This time, “Application of Electronic Technique” magazine invited honored guests from six global automation giants, including ABB, Emerson, Schneider Electric, Siemens, Rockwell Automation, Festo, and two leading electronic manufacturing companies in the world: USI and Applied Materials, to express their views on the transformation of enterprises in the era of industrial Internet and talk about intelligent manufacturing themed by "Automation Giants Embrace the Era of Industrial Internet".

// The birth of the global leader in electronic design and manufacturing //

USI Milestone

Established in 1976, USI was listed on the Shanghai A-share main board in 2012 (SSE stock code: 601231). In 2014, it became an industry leader in the SiP (System-in-Package) module field; in 2020, the Company completed the acquisition of Asteelflash, the second-largest EMS company in France. With a deep accumulation of electronics manufacturing technology, USI (Universal Scientific Industrial (Shanghai) Co., Ltd.) is a provider of D(MS)2 product services for well-known brand manufacturers at home and abroad: design, manufacturing, miniaturization, solutions, and services. The industry services provided by the Company include five categories of electronic products: communications, computers and storage, consumer electronics, industrial and medical electronics, and automotive electronics.

As a large-scale design and manufacturing service provider of professional design and solutions for global electronic products, USI pays great attention to and emphasizes the links of solution and service, focuses on the core idea of creating value for customers, expands high-quality customers and establishes closer cooperative relations with customers, so the Company has gradually developed from a manufacturing service provider to a system solution provider and an integrated service provider in the field of products it provides. It is also worth mentioning that USI has factories all over the world. Since 1997, its factories in Mexico, Shenzhen, the United States, Shanghai, Poland, and other places have been established. After the acquisition of Asteelflash in France, the Company has 27 production bases around the world, including 9 in Asia, 3 in the Americas, 14 in Europe, and 1 in Africa, fully adapting to the trend of "global demand and localized services".

// Intelligent manufacturing, one of the important business strategies of USI //

As a global leader in electronic design and manufacturing, "intelligent manufacturing" has always been one of USI's important business strategies. In the context of countries all over the world promoting the transformation of manufacturing to intelligence and automation, as a company, it is only by looking at technology from a business perspective and choosing the direction of transformation that the Company can deal with all this calmly. According to USI, automation is not simply about replacing labour with robots, but more importantly about “optimizing the existing manufacturing process through the introduction of intelligent automation", e.g., improving product quality, enhancing process stability, and strengthening the ability to deliver the goods in time, etc. USI has been investing in equipment automation for many years, helping customers gain competitiveness through intelligent automation strategies. Now, USI has begun to develop and implement Industry 4.0 data automation to improve the Company's future competitiveness.

// Dialogue with Cao Jing: The "Global 5-star Industry 4.0 Intelligent Manufacturing Program" contributes to automation manufacturing in USI's global factories //

Q1: In the era of the industrial Internet, what innovations has USI made in technology?

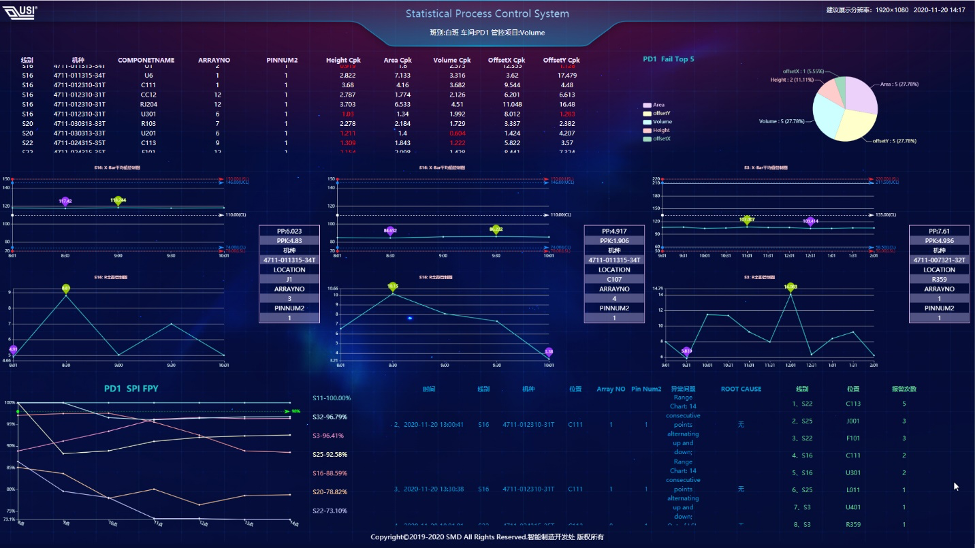

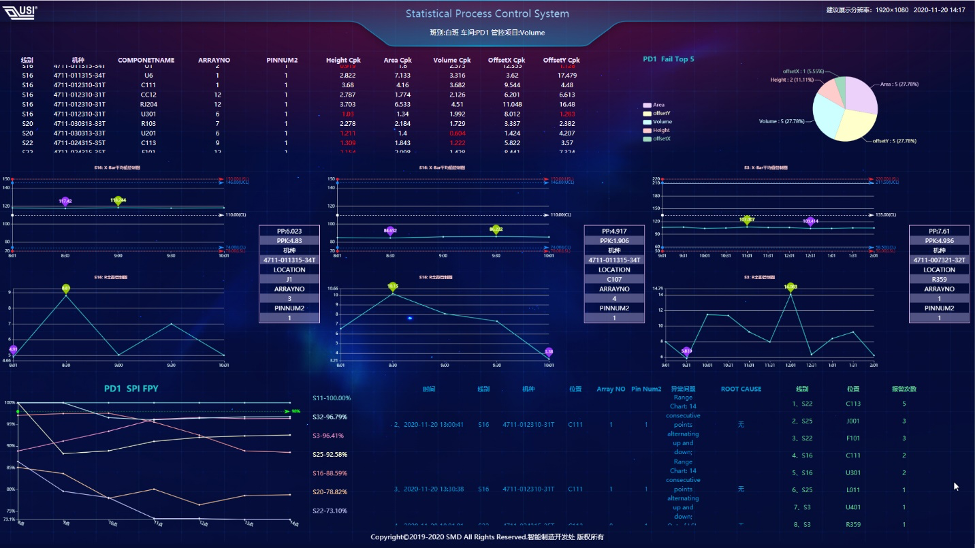

Cao Jing: USI has almost used all mainstream I4.0 automation technologies to realize our intelligent manufacturing roadmap. The technologies that have been introduced include the inhouse automation equipment communication network that supports 5G and 4G, automated material handling systems (AMHS), unmanned testing workshops with fully automated robot arms, and real-time production equipment status monitoring system with remote access instrument boards. Artificial Intelligence (AI) online SPC is used for process control of key production equipment, real-time environmental monitoring and alarm system for clean room, AGV-based production workshop WIP (Work-In-Progress) transmission system, recipe management system (RMS), fully automated 6-sided product inspection system, and various production equipment data automation applications.

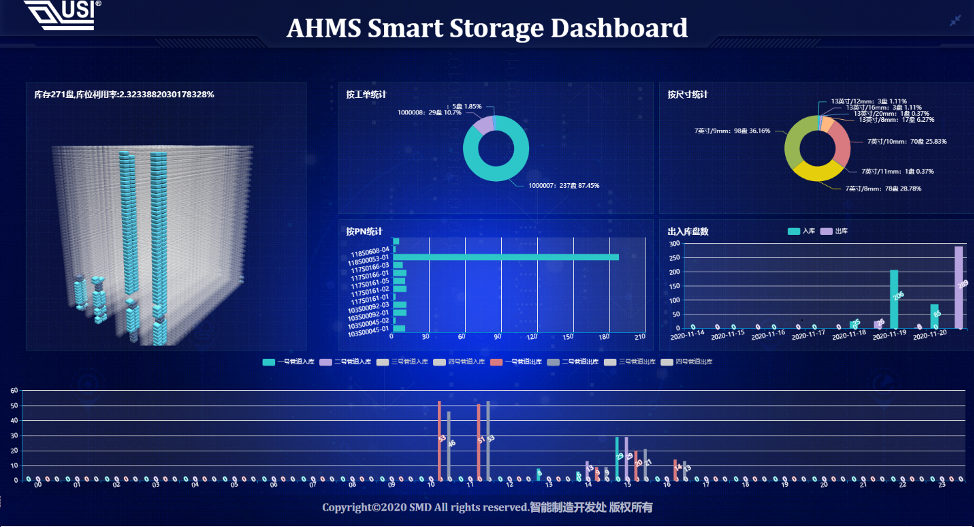

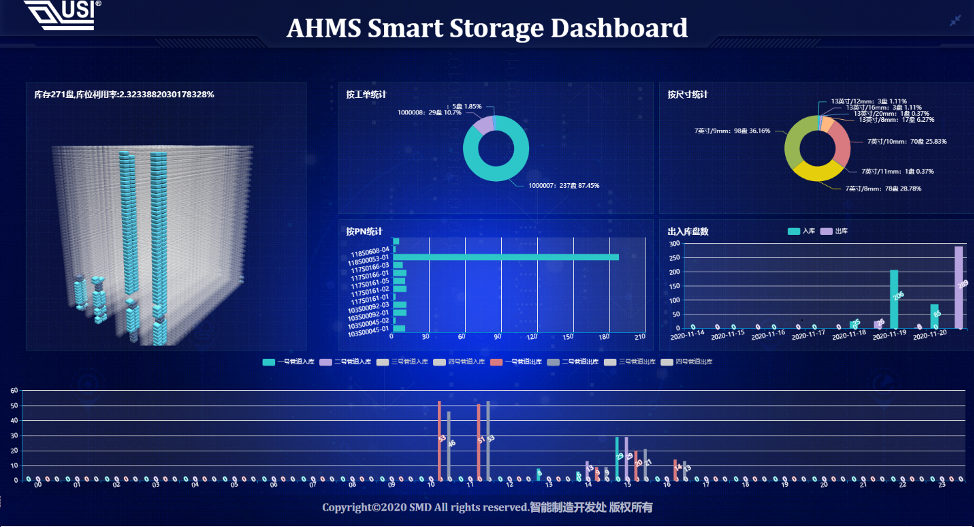

Take the AMHS system as an example. From the arrival of the parts to the warehouse, to the delivery of parts to each SMT chip mounter by the AGV in the Just-in-Time mode, the entire process is fully automated. Therefore, we can save the preparation room and related material handling work. Each machine is connected to a workshop management system, and the workshop management system is connected to our ERP system. Our data automation is integrated with the workshop management system, so we can accurately know the exact time when each machine runs out of materials. The AMHS system can automatically allocate and transport the correct parts from the robot-driven intelligent storage device to the corresponding machine.

AMHS

Q2: How does USI plan the transformation? What kind of strategy do you have?

Cao Jing: USI has a very detailed industry 4.0 intelligent manufacturing development plan, which we call the global 5-star industry 4.0 intelligent manufacturing. This plan sets out our phased development in the next five to seven years to improve the automated manufacturing level of our global factories. We will review the system month by month and rate the progress made by all factories at the end of the year.

USI's business can be divided into two parts: SiP system packaging (System-in-Package) and EMS. The process flow of SiP system packaging is very similar to typical IC packaging and testing, the main difference is that we use SMT instead of wirebond, and the back-end and testing processes are very similar, but the production of SiP modules is much more difficult than the production of single-chip IC products. Not all of our factories are at the same level. Our intelligent manufacturing development team develops a common platform in the Shanghai factory. Our strategy is to use this common platform to standardize data automation protocols and equipment, and then introduce it globally according to the needs of each factory.

Common Platform

Our current strategy is to transform labour-intensive manufacturing into high-productivity intelligent manufacturing. The intelligent manufacturing department develops a common automation platform and data automation application modules for each station that needs automation and then promotes it to all factories that need automation, so that we can enhance efficiency with more effective development costs and shortened introduction period.

Q3: The integrated development of 5G and industrial Internet is a necessary choice for the evolution of the two technologies. How does USI embrace the new era of 5G?

Cao Jing: Our vision is to realize the overall I4.0 intelligent manufacturing through the 5G in-plant network, connect all production and test equipment to the central server and each engineer, and increase the data transmission rate of the network to speed up the reaction time of production. We cooperate with local 5G telecom service operators to build in-house private networks to support factory automation networks. Of course, we also adopt the 4G network with relatively low cost at present according to specific application requirements to maximize cost-effectiveness.

Q4: Information security serves as the "base" for the development of the industrial Internet. What do you think of the security risks of the industrial Internet? What measures does USI take to avoid such risks?

Cao Jing: With the development of cutting-edge technology and business development, we have noticed a sharp increase in information security threats in industrial control systems. The first common threat is the ICS system (Industrial Control System) exposed on the Internet. We have deployed network partition and firewalls to protect our network environment and core capabilities from attacks. The second threat is weak isolation from the perspective of applications and systems. We implement due diligence and separation of duties to protect our environment and further reduce the possibility of unauthorized access and the spread of malware. The third threat is the lack of security awareness. We have developed a comprehensive security awareness program to increase the awareness of end-users and will popularize it to all bases around the world. We are applying our information security capabilities in an OT (Operational Technology) environment to build a stronger and safer environment.

Q5: What do you think of the development maturity of the industrial Internet? What opportunities and challenges is USI still facing?

Cao Jing: It is still in its infancy at present, and will be quickly and fully implemented in all factories in the next 3 to 5 years. We are technically capable, but the initial investment cost remains a challenge, and there is the issue of I4.0 automation talents. We invest in order of priority to balance and gradually realize short-term benefits and long-term returns. This is the best way to continuously improve our cost competitiveness and manufacturing capabilities in the next few years. Another major challenge is that our current talents in the development and introduction of I4.0 5G network applications are still insufficient to a certain extent. It takes time to cultivate talents, and with the huge market demand, it is a major challenge to recruit experienced automation engineers, so we must also train talents as soon as possible to meet the challenges.

[Application of Electronic Technique - Top Interview] 2021.07.12

Reporter | Wei Xiaowei

[Editor's Note]

The "14th Five-year Plan" period is a key stage for the industrial Internet, together with 5G, big data, artificial intelligence, and other new-generation information technologies, to accelerate the transformation and upgrading of the manufacturing industry. The industrial Internet is reshaping the ecology of the manufacturing industry, and makes everything look new and fresh. This time, “Application of Electronic Technique” magazine invited honored guests from six global automation giants, including ABB, Emerson, Schneider Electric, Siemens, Rockwell Automation, Festo, and two leading electronic manufacturing companies in the world: USI and Applied Materials, to express their views on the transformation of enterprises in the era of industrial Internet and talk about intelligent manufacturing themed by "Automation Giants Embrace the Era of Industrial Internet".

// The birth of the global leader in electronic design and manufacturing //

USI Milestone

Established in 1976, USI was listed on the Shanghai A-share main board in 2012 (SSE stock code: 601231). In 2014, it became an industry leader in the SiP (System-in-Package) module field; in 2020, the Company completed the acquisition of Asteelflash, the second-largest EMS company in France. With a deep accumulation of electronics manufacturing technology, USI (Universal Scientific Industrial (Shanghai) Co., Ltd.) is a provider of D(MS)2 product services for well-known brand manufacturers at home and abroad: design, manufacturing, miniaturization, solutions, and services. The industry services provided by the Company include five categories of electronic products: communications, computers and storage, consumer electronics, industrial and medical electronics, and automotive electronics.

As a large-scale design and manufacturing service provider of professional design and solutions for global electronic products, USI pays great attention to and emphasizes the links of solution and service, focuses on the core idea of creating value for customers, expands high-quality customers and establishes closer cooperative relations with customers, so the Company has gradually developed from a manufacturing service provider to a system solution provider and an integrated service provider in the field of products it provides. It is also worth mentioning that USI has factories all over the world. Since 1997, its factories in Mexico, Shenzhen, the United States, Shanghai, Poland, and other places have been established. After the acquisition of Asteelflash in France, the Company has 27 production bases around the world, including 9 in Asia, 3 in the Americas, 14 in Europe, and 1 in Africa, fully adapting to the trend of "global demand and localized services".

// Intelligent manufacturing, one of the important business strategies of USI //

As a global leader in electronic design and manufacturing, "intelligent manufacturing" has always been one of USI's important business strategies. In the context of countries all over the world promoting the transformation of manufacturing to intelligence and automation, as a company, it is only by looking at technology from a business perspective and choosing the direction of transformation that the Company can deal with all this calmly. According to USI, automation is not simply about replacing labour with robots, but more importantly about “optimizing the existing manufacturing process through the introduction of intelligent automation", e.g., improving product quality, enhancing process stability, and strengthening the ability to deliver the goods in time, etc. USI has been investing in equipment automation for many years, helping customers gain competitiveness through intelligent automation strategies. Now, USI has begun to develop and implement Industry 4.0 data automation to improve the Company's future competitiveness.

// Dialogue with Cao Jing: The "Global 5-star Industry 4.0 Intelligent Manufacturing Program" contributes to automation manufacturing in USI's global factories //

Q1: In the era of the industrial Internet, what innovations has USI made in technology?

Cao Jing: USI has almost used all mainstream I4.0 automation technologies to realize our intelligent manufacturing roadmap. The technologies that have been introduced include the inhouse automation equipment communication network that supports 5G and 4G, automated material handling systems (AMHS), unmanned testing workshops with fully automated robot arms, and real-time production equipment status monitoring system with remote access instrument boards. Artificial Intelligence (AI) online SPC is used for process control of key production equipment, real-time environmental monitoring and alarm system for clean room, AGV-based production workshop WIP (Work-In-Progress) transmission system, recipe management system (RMS), fully automated 6-sided product inspection system, and various production equipment data automation applications.

Take the AMHS system as an example. From the arrival of the parts to the warehouse, to the delivery of parts to each SMT chip mounter by the AGV in the Just-in-Time mode, the entire process is fully automated. Therefore, we can save the preparation room and related material handling work. Each machine is connected to a workshop management system, and the workshop management system is connected to our ERP system. Our data automation is integrated with the workshop management system, so we can accurately know the exact time when each machine runs out of materials. The AMHS system can automatically allocate and transport the correct parts from the robot-driven intelligent storage device to the corresponding machine.

AMHS

Q2: How does USI plan the transformation? What kind of strategy do you have?

Cao Jing: USI has a very detailed industry 4.0 intelligent manufacturing development plan, which we call the global 5-star industry 4.0 intelligent manufacturing. This plan sets out our phased development in the next five to seven years to improve the automated manufacturing level of our global factories. We will review the system month by month and rate the progress made by all factories at the end of the year.

USI's business can be divided into two parts: SiP system packaging (System-in-Package) and EMS. The process flow of SiP system packaging is very similar to typical IC packaging and testing, the main difference is that we use SMT instead of wirebond, and the back-end and testing processes are very similar, but the production of SiP modules is much more difficult than the production of single-chip IC products. Not all of our factories are at the same level. Our intelligent manufacturing development team develops a common platform in the Shanghai factory. Our strategy is to use this common platform to standardize data automation protocols and equipment, and then introduce it globally according to the needs of each factory.

Common Platform

Our current strategy is to transform labour-intensive manufacturing into high-productivity intelligent manufacturing. The intelligent manufacturing department develops a common automation platform and data automation application modules for each station that needs automation and then promotes it to all factories that need automation, so that we can enhance efficiency with more effective development costs and shortened introduction period.

Q3: The integrated development of 5G and industrial Internet is a necessary choice for the evolution of the two technologies. How does USI embrace the new era of 5G?

Cao Jing: Our vision is to realize the overall I4.0 intelligent manufacturing through the 5G in-plant network, connect all production and test equipment to the central server and each engineer, and increase the data transmission rate of the network to speed up the reaction time of production. We cooperate with local 5G telecom service operators to build in-house private networks to support factory automation networks. Of course, we also adopt the 4G network with relatively low cost at present according to specific application requirements to maximize cost-effectiveness.

Q4: Information security serves as the "base" for the development of the industrial Internet. What do you think of the security risks of the industrial Internet? What measures does USI take to avoid such risks?

Cao Jing: With the development of cutting-edge technology and business development, we have noticed a sharp increase in information security threats in industrial control systems. The first common threat is the ICS system (Industrial Control System) exposed on the Internet. We have deployed network partition and firewalls to protect our network environment and core capabilities from attacks. The second threat is weak isolation from the perspective of applications and systems. We implement due diligence and separation of duties to protect our environment and further reduce the possibility of unauthorized access and the spread of malware. The third threat is the lack of security awareness. We have developed a comprehensive security awareness program to increase the awareness of end-users and will popularize it to all bases around the world. We are applying our information security capabilities in an OT (Operational Technology) environment to build a stronger and safer environment.

Q5: What do you think of the development maturity of the industrial Internet? What opportunities and challenges is USI still facing?

Cao Jing: It is still in its infancy at present, and will be quickly and fully implemented in all factories in the next 3 to 5 years. We are technically capable, but the initial investment cost remains a challenge, and there is the issue of I4.0 automation talents. We invest in order of priority to balance and gradually realize short-term benefits and long-term returns. This is the best way to continuously improve our cost competitiveness and manufacturing capabilities in the next few years. Another major challenge is that our current talents in the development and introduction of I4.0 5G network applications are still insufficient to a certain extent. It takes time to cultivate talents, and with the huge market demand, it is a major challenge to recruit experienced automation engineers, so we must also train talents as soon as possible to meet the challenges.