Environmental Protection and Occupational Safety

Pollution Control

USI integrates the environment sustainable development principle with business decision-making and operation management. Internal employees' awareness of environmental protection are trained, and material environmental consideration items are identified continuously, such as air pollution, water pollution, wastes, toxic chemicals, noise pollution, soil pollution and energy resources are improved. We are committed to improving and reducing the negative impact of business operations on the environment. Furthermore, we also publicly disclose the Company's environmental information and fulfill corporate environmental responsibilities.

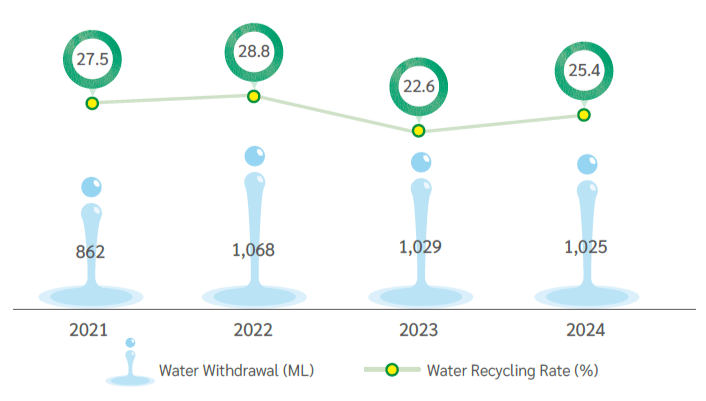

USI does not have issues with contaminating catchment areas as our facilities are not built around it. But Mainland China's regulation has become increasingly rigorous and ASEH paid close attention, the storage and distribution of water resources have also become an important topic for us. Based on the emphasis on water resources, USI remains committed to water conservation in production and daily life. The factory regularly provides employees with water reduction-related education and training. The courses aims to enhance the concept of reducing water consumption so that employees can discover opportunities to save water in their daily activities, and provide them with the opportunity to propose continuous improvement projects. USI strives to conserve water in manufacturing and everyday life by installing water meters and monitoring monthly water usage data to manage water resources and identify opportunities for conservation by water use assessments.

Apart from regularly tracking the water consumption of the seven major manufacturing facilities, each facility will separate and collect process chemicals for treatment, set up discharge water treatment facilities for water quality management, and regularly outsource the testing of discharge water quality to prevent the occurrence of incidents of contamination of water sources.

In order to make full use of water resources, USI has enhanced the reuse of water resources by improving equipment and technology. USI's total water consumption in 2024 will be 1,024.70 million liters, a decrease of 0.4% from 2023 (1,028.62 million liters), which is water intensive. The water consumption rate dropped by 19.3% compared with 2015, achieving the water saving target. In addition, the recycled water volume was 260.24 million liters, with a total recovery rate of 25%, and the process water consumption was 204.47 million liters, with a process water recovery rate of 65%.

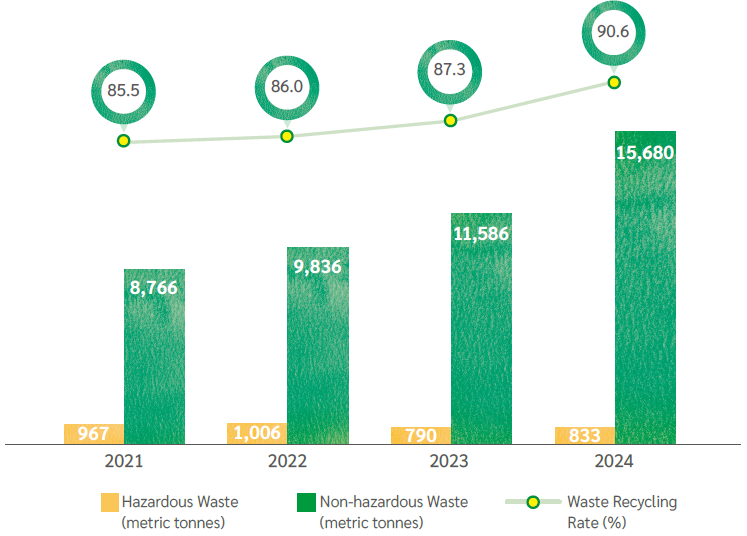

USI considers "Waste Minimization and Reuse" as corporate policy. The principles of "Impact Mitigation & Continuous Improvement" and "Effective Reduction & Circular Reuse" have been carried out thoroughly in all the facilities and treated as annual performance indicator. Therefore, through regular data record and tracking, the relevant units such as process unit, facility affairs unit, and EHS unit strictly monitor the usage and outputs, and strengthen the effective control of waste. To identify opportunities for improving waste performance, the Zhangjiang Facility, Jinqiao Facility, Huizhou Facility, Kunshan Facility, Nantou-TT, and Nantou-NK Facilities have achieved zero landfill waste through regular audits.

The total amount of waste generated in 2024 was 16,513 metric tonnes, and recycled 14,964 metric tonnes, with a recycling rate of 90.6%. Although it is a slight increase from the previous year, it still meets the annual target (80%); The non-hazardous waste recycling rate of 94.1% also meets the annual target (90%), the details are shown as follows.

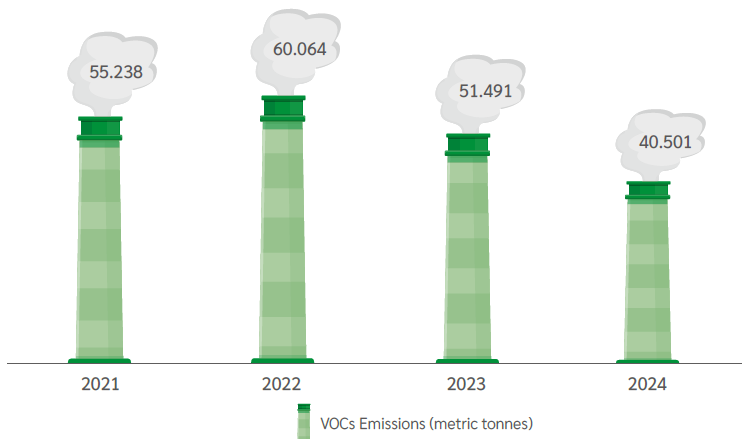

In recent years, air pollution is getting worse in Mainland China and Taiwan. It seriously affected the quality of life for residents that become an urgent issue. This is the reason that local authority has made relevant amendments to local regulations. As our production facilities are within the affected areas, we also pay great attention to air pollutant control within our facilities.VOCs emissions in 2024 will be 40.501 metric tonnes, a decrease of 21.3% from the previous year. The overall emissions of VOCs have gradually been reduced.

For NOx, SOx, and PM emissions, since 2019, Since 2019, Jinqiao Facility has also upgraded its boiler systems with low-nitrogen burners to reduce NOx emissions. Other facilities have adopted technologies such as UV photodegradation, activated carbon treatment, and zeolite rotor systems combined with catalytic thermal oxidizers. Nantou Facility undergoes regular inspections and reporting as mandated by local authorities, and in 2023, the Nantou-NK1 Facility installed a zeolite rotor and rotary regenerative oxidizer to further reduce VOCs. Additionally, Mexico Facility began PM testing in accordance with local regulatory requirements.

Moving forward, USI will continue to expand transparency by disclosing air pollutant data across more facilities and actively promoting the adoption of emission reduction measures company wide. Detailed air pollutant emissions data for 2024 is presented in the table below:

| Pollutant | Zhangjiang | Jinqiao | Huizhou | Kunshan | Nantou TT |

Nantou NK |

Mexico | Vietnam |

|---|---|---|---|---|---|---|---|---|

| Volatile Organic Compounds (VOCs) |

3.979 | 1.101 | 1.531 | 1.950 | 12.047 | 19.893 | N/A | N.D |

| Nitrogen Oxides (NOx) |

0.040 | 0.047 | N.D. | N.D. | N/A | 3.986 | N/A | N/A |

| Sulfur Oxides (SOx) |

N.D. | N.D. | N.D. | N.D. | N/A | 0.609 | N/A | N/A |

| Particulate Matter (PM) |

0.587 | 0.109 | 0.141 | N.D. | 0.002 | 0.841 | 2.140 | 9.985 |

Note: N/A: No applicable local regulation and no available self-testing data.; N.D.: Non-Detectable, the level is too low to be detected by the instrument.