Green Products and Innovation

Sustainable Raw Materials

USI is committed to sustainable raw materials sourcing practices through detoxification, decarbonization, and dematerialization while avoiding human rights infringements.

We recognize that establishing transparent and responsible raw materials management in the supply chain is pivotal for avoiding operational disruptions due to critical raw material scarcity, mitigating negative impacts on the environment and society, and preserving resource sustainability. This Sustainable Raw Materials Policy is thus ratified and endorsed by the Board of Directors.

USI follows its sustainable raw materials policy to tracking and collecting data about the sources of raw materials and upstream suppliers, risk assessment, and carry out coordinated actions. For detailed procedures, please refer to the relevant Management Measures.

SDGs 12, Responsible Consumption and Production, calls on countries to promote a circular economy model that keep resources circulating within the product supply chain, extend product lifespans, and reduce waste generation to support a green economy. Therefore, we collected information on all new mass-produced products in 2024 that comply with the WEEE reporting requirements, and compiled statistics for Material Usage and Recycling Ratio in Products.

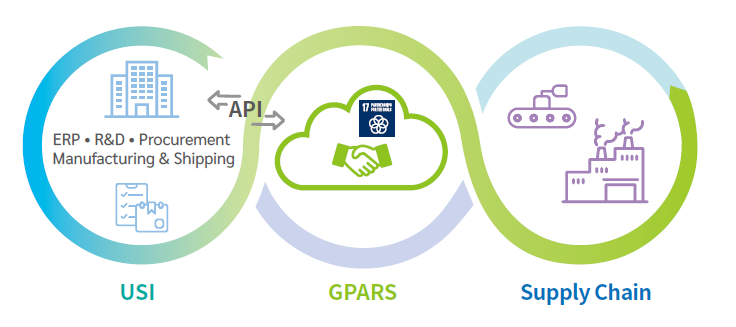

We design green products that meet global regulations based on the four aspects of Green Product Eco-design and introduced a professional green value chain management platform Green Parts Aggregations & Reporting System (GPARS) and Green Parts (GP) database to manage the materials we use in our products and whether they meet the latest relevant requirements that include but are not limited to Hazardous Substance Free (HSF), RoHS, REACH, USI Green Environmental Protection Products Requirements and conduct a reasonable degree of investigation on the country of origin of the minerals and assess their priority as sustainable raw materials.

Our suppliers must provide Environmental Hazard Non-Use Declaration, material composition tables and verification reports, all raw materials are 100% in line with sustainable risk assessment results, including human rights, climate, biological and other factors to ensure that the purchased parts and materials are 100% in compliance with company specifications. The trend toward green products is inevitable. Industries could face upcoming challenges only by establishing a long-lasting sustainable green supply chain, our management process as detailed in the Sustainable Supply Chain section.

GPARS System

We follow the IECQ QC080000 Hazardous Substances Process Management System Standard, and establish green parts/material management and control procedures to achieve products that meet international and customer standards for no hazardous substances.

USI's suppliers must confirm all provided components, non-BOM and packaging materials, and report back to USI via GPARS or Questionnaire methods for any containing hazardous substances. The main management requirements are as follows:

- Restriction of Hazardous Substances (RoHS) directive mainly regulates the material and technical standards of electronic and electrical products, requiring that the use of lead, mercury, cadmium, hexavalent chromium, PBB, PBDE, DEHP, BBP, DBP, and DIBP in electronic products is prohibited in order to achieve environmental and human health the purpose of protection.

- Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) is a statutory ordinance that compulsory registration, evaluation, permitting, and monitoring of chemicals entering the EU market. The bill raises the quality requirements and entry barriers for products from different countries and regions to enter the EU.

- For the candidate list of Substances of Very High Concern (SVHC) in REACH, suppliers must confirm all provided materials for any SVHC substances at/or above the 0.1% weight by weight (w/w) concentration and ban the use of Annex XVII list of dangerous substances.

- For current SVHC candidate list, please visit ECHA: https://echa.europa.eu/candidate-list-table

- For current Annex XVII list, please visit ECHA: https://echa.europa.eu/substances-restricted-under-reach

- California Proposition 65, officially known as the Safe Drinking Water and Toxic Enforcement Act of 1986. The proposition protects the state's drinking water sources from being contaminated with chemicals known to cause cancer, birth defects or other reproductive harm, and requires businesses to inform Californians about exposures to such chemicals.

- For current Proposition 65 list, please visit OEHHA: https://oehha.ca.gov/proposition-65/proposition-65-list

- The Toxic Substances Control Act (TSCA) is a U.S. law that was implemented by the U.S. Environmental Protection Agency (EPA) in 1976. TSCA prohibits the production or import of chemicals that are not on the TSCA list or subject to exemptions. Chemicals listed in TSCA are called Existing Chemicals, while chemicals not listed are called new chemicals. Manufacturers must submit a pre-manufacturing notice to the EPA before manufacturing or importing new chemicals for commercial use.

- For current TSCA control list, please visit TSCA: https://www.epa.gov/chemicals-under-tsca

- PFAS refers to any chemical substances containing at least one perfluorinated methyl group (-CF3) or a perfluorinated methylene group (-CF2-), and such substances are equipped with the waterproof and oilproof characteristics while exhibiting excellent chemical resistance and thermal resistance. They are widely used in adhesives, coating materials, inks, and plastic materials. The carbon-fluorine bond is extremely strong and stable, and it cannot be disintegrated by the environment, such that it may eventually become a permanent organic pollutant.

- The EU has announced the PFAS restriction proposal in 2023, and it is expected to be promulgated and implemented 2025-2027.

In addition, the partial list of banned substances and requirements, please refer to the attached table:

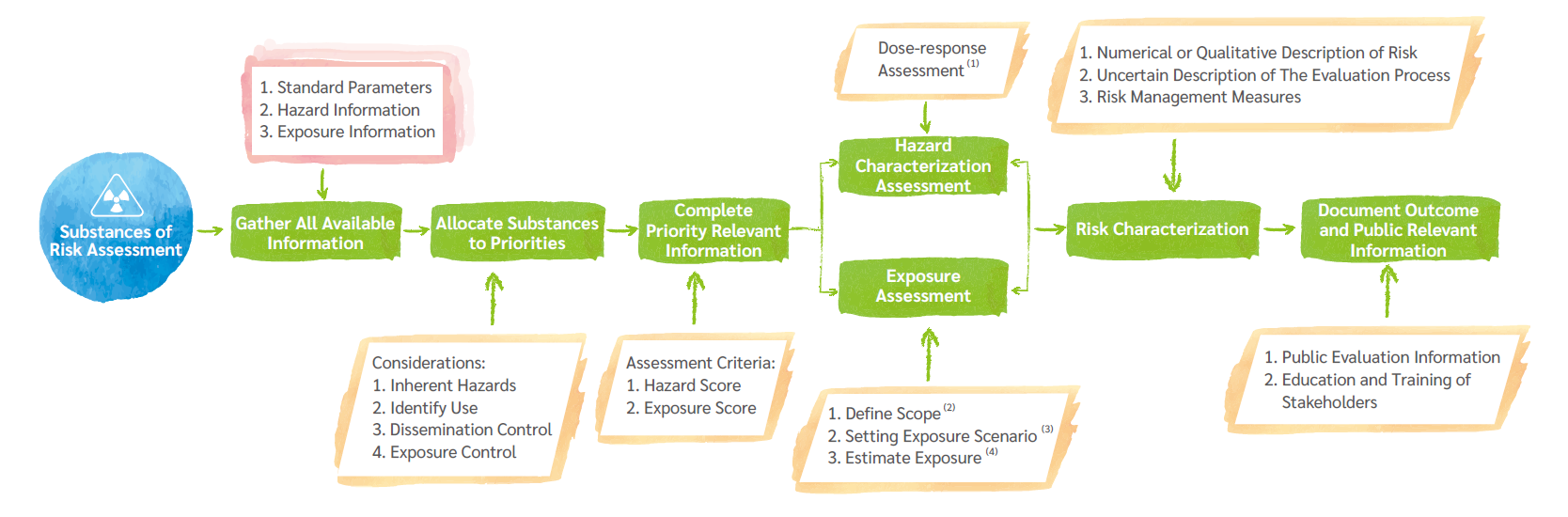

USI's Hazardous Substance Risk Assessment process includes the management of hazardous substances in products and chemicals used in production. We evaluate hazardous substance risks and opportunities based on frequency of occurrence, frequency of exposure, and degree/severity of impact, and the higher the risk multiplier score, the higher the risk level. The Company uses the risk level identification to propose countermeasures to reduce the potential impacts on human health and the environment.

Hazardous Substance Risk Assessment Process

Note:

1. Dose-response assessment include the human health hazard, physicochemical hazard, environmental hazard, persistent, bioaccumulative and toxic (PBT) and very persistent and very bioaccumulative (vPvB).

2. Define scope include the material manufacturing, use and exposure information.

3. Setting exposure scenario include the used scope, usage, possible exposure routes and exposure control measures.

4. Estimate exposure include the worker exposure/concentration or environmental exposure concentration.

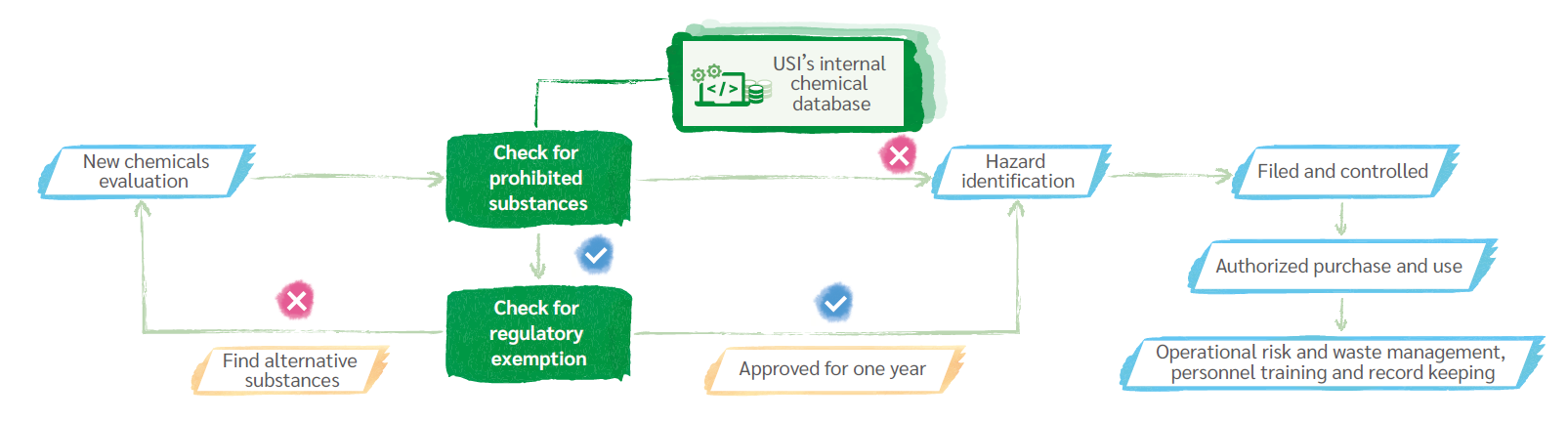

We developed our Chemical Management Procedure, so chemicals are controlled and used in ways that minimize adverse impacts on the environment and human health. The key to our Procedure is a comprehensive review of substances and all applicable chemical regulations and use restrictions. We grade chemicals according to environmental and safety risks and constantly update them into our database. As part of source control, chemicals must be checked against the database, reviewed, and filed before they can be procured and subsequently introduced into our manufacturing process. Regarding the transportation, loading and unloading, storage, handling, labeling, use, pollutant management, and emergency measures for chemicals, all relevant personnel are required to undergo both pre-assignment and regular training, and training records must be properly maintained.

Chemical Safety Management Process

For relevant risk level definitions and statistics on prohibited and restricted substances, please refer to the attached file:

To made stakeholders further aware of the importance of environment protection and applied the correct environmental concepts to various steps in production process (i.e., the product planning, raw material control and GHG emission reduction). We keep communicating with employees, suppliers and contractors regarding our EHS-associated principles, knowledge, and requirements. The e-learning courses on sustainable green production train employees in R&D, procurement, and quality control departments on GP-related regulations, requirements, procedures, and eco-friendly materials. In 2024, all facilities implemented 16,520 lessons (8,069 hours).