Value Chain Management

Customer Relations

Since its inception, the Company has been providing professional services and quality products to meet the diverse needs of our customers. We possess cutting-edge product development and manufacturing capabilities to provide customers with complete services from design to distribution and services spanning across global production locations. Delivering complete solutions with a focus on customer satisfaction is our core value.

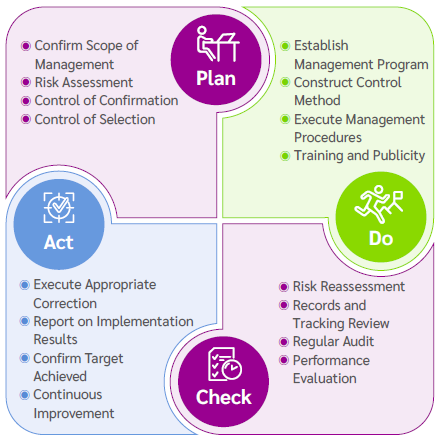

Quality Management

We have established a comprehensive quality management system and formulated our Quality Policy Quality Policy and we implement the PDCA cycle to conduct quality inspections, quality audits, and other management activities, promoting process management methods, risk assessment, and control measures to eliminate potential risks and drive continuous improvement. We ensure the compliance and effectiveness of our quality and hazardous substance management systems through internal audits and continuous improvement. Our commitment to quality drives us to deliver high-standard products and services that meet global customer expectations.

Driving Up Customer Satisfaction

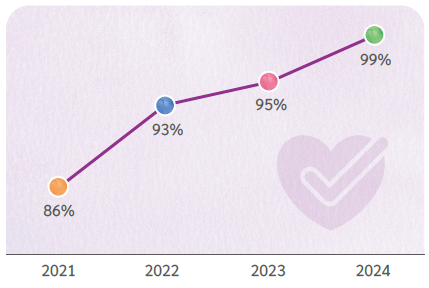

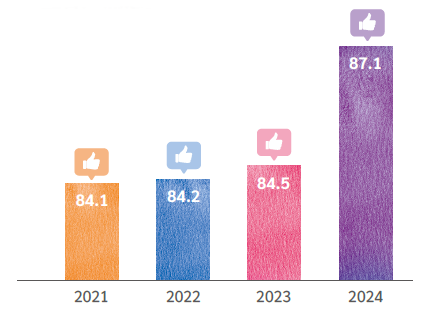

USI offers a full range of services tailored to customer needs. We communicate effectively with our customers worldwide and proactively collect valuable feedback and concerns through regular. In the 2024 customer satisfaction1 survey that covers all customers, 99% were satisfied with USI's services, and the customer satisfaction score averages 87.1 across all satisfaction dimensions. USI actively fosters deep communication and collaboration with customers, aiming to further elevate satisfaction and co-create greater value in the electronics design industry.

Percentage of Satisfied Customers:

Customer Satisfaction Score:

Note:

1. Definition of Customer Satisfaction Score: Outstanding Satisfaction ≥ 90;Excellent Satisfaction ≥ 85;Successful Satisfaction ≥ 80;Satisfied Satisfaction ≥ 70;Improvement Required Satisfaction≥ 60;Unacceptable Satisfaction < 60

Customer Privacy Protection

Customer confidential information is regarded as a critical asset and a cornerstone of mutual trust. Our company is deeply committed to safeguarding customer privacy and the integrity of confidential data. To ensure this, we enter into non-disclosure agreements (NDAs) with our clients, with contractual provisions explicitly outlining our responsibility to protect such information, and we have also established privacy and personal information protection policies that serve as the basis for compliance management. This includes managing the collection, processing, and use of personal information, and practicing privacy and personal information protection.

Regarding customer document management, the Company stipulates that all customer documents are defined to have the highest level of confidentiality to protect product information provided by customers. Information authorization management is adopted to ensure that customer privacy is tightly protected. For information security management, implement information security policies through various management systems and management committees, strengthen the information security environment and information security incident response capabilities, and protect the Company's intellectual property and customer data from leakage or unauthorized access. Please refer to the Information Security Management.