Search

- 07/25/2023

Building Blocks of Performance: Importance of PCB Material Selection for PCIe Gen5

The evolution to PCIe Gen5 technology underscores the importance of PCB material selection, a critical building block for overall system performance. The higher data rates PCIe Gen5 offers, up to 32 GT/s, demand PCB materials that ensure minimal signal loss and maximum data integrity. The materials must possess excellent dielectric constant(Dk) properties, low loss tangent(Df), and strong thermal Conductivity to handle the heat generated at faster speeds. The right PCB material can help ensure that the high-speed, high-density advantages of PCIe Gen5 are fully leveraged, significantly boosting system performance.

When crafting the blueprint of a Printed Circuit Board (PCB) or manufacturing it, a crucial aspect often not given due attention is the base material selection. The choice of material carries immense significance as it can significantly impact not just the board's functionality but also its lifespan and compatibility with other hardware components.

This detailed exploration will shed light on the vital role of PCB material for PCIe Gen5 selection and broaden our understanding of thermal Conductivity, Conductivity, and cooling strategies. We will also delve into approaches to evaluating the performance of a PCB.

Category

1) The Central Role of Material Selection in PCB Design

2) Key Factors to Consider in Material Selection

3) Understanding Dielectric Constant and Loss Tangent

4) Assessing PCB Performance

5) Take Care from the Very Beginning of the Journey

6) FAQs

The Central Role of Material Selection in PCB Design

The choice of material for your PCB transcends the mere consideration of financial investment. The selected material carries the weight of determining how your PCB will perform under different environmental and operational conditions, its overall robustness and resistance to wear and tear, as well as its interplay with other system components. Material selection is especially critical in high-speed or high-frequency designs, where properties such as dielectric constant and loss tangent can dramatically impact performance.

Commonly used PCB materials for PCIe Gen5 include FR-4, Polyimide, PTFE, Rogers, and more, each with unique properties. When selecting PCB material, designers must consider various factors, including the operating environment, required electrical performance, cost, manufacturability, and lead times.

Key Factors to Consider in Material Selection

- Operating Environment: The operating environment of the PCB, which can be commonly named as humidity, temperature, and also chemicals exposure, should be taken into account. Certain materials may perform better in specific conditions, ensuring the reliability of the electronic system.

- Required Electrical Performance: Different applications demand specific electrical performance from the PCB. Parameters like dielectric constant, loss tangent, and metal surface roughness are critical in determining signal integrity and speed.

- Cost: Cost is often a significant consideration in any design project. Designers must strike a balance between performance and budget constraints, making cost-effective choices without compromising quality.

- Manufacturability: The selected material should be easily manufacturable into the desired PCB design, ensuring a smooth production process.

- Lead Times: Projects often have tight deadlines, and selecting materials with shorter lead times can be advantageous to meet project schedules.

Understanding Dielectric Constant and Loss Tangent

Dielectric Constant (Dk)

The Dielectric Constant (Dk) is a measurement to present the ability of a material in storing electrical energy in an electric field. In simpler terms, it measures how much a material will slow down the signal on the trace. A lower Dk value indicates a faster signal propagation speed and less signal loss. Dk is a critical parameter in high-speed and high-frequency designs, influencing impedance, signal speed, and signal integrity.

Loss Tangent (Df)

On the other hand, the Loss Tangent or Dissipation Factor (Df) measures how much signal is lost as heat travels along the trace. A lower Df means lower signal loss and is particularly crucial in high-frequency applications where high signal loss can degrade performance.

Metal Surface Roughness

Whether the metal surface is rough or not, the loss generated in high-speed signals above 1GHz becomes more severe. Due to the issue of metal surface roughness, the loss incurred in PCIe Gen4 or PCIe Gen5 accounts for approximately 3-4%. Therefore, the selection of metal materials has also become a critical parameter in PCB design in recent years.

These two parameters are vital when selecting PCB materials for PCIe Gen5, especially for high-speed or high-frequency designs. Below are some examples and applications for each of the mentioned materials:

1. FR-4

FR-4 is a widely used and cost-effective PCB material suitable for a broad range of applications. It is commonly used in consumer electronics, automotive systems, and industrial control systems. However, due to its relatively higher Dk value, it may not be the best choice for ultra-high-speed designs.

2. Polyimide

Polyimide is well known for its excellent heat dissipation stability and flexibility, making it suitable for applications requiring high-temperature resistance. It is often used in aerospace, military, and medical devices where reliability and performance under harsh conditions are essential.

3. PTFE (Teflon)

PTFE is renowned for its low Dk value and excellent electrical properties. It is a top choice for high-frequency applications, including microwave and RF circuits. Low signal loss and stable performance over a wide temperature range make it ideal for critical communication systems.

4. Rogers

“Rogers” is a well-known Corporation in the industry that offers a range of high-frequency laminates with varying Dk values designed explicitly for demanding RF and microwave applications. They are widely used in telecommunications, satellite communication, radar systems, and other wireless devices.

Assessing PCB Performance

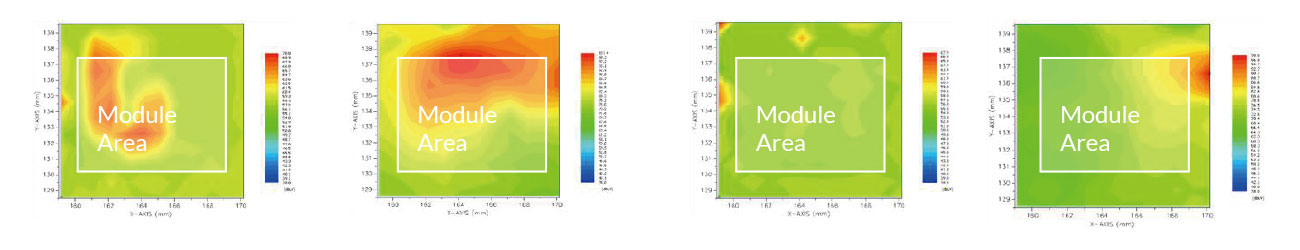

Once a PCB takes its final form, it is paramount to evaluate its performance to affirm that the board aligns with the predefined specifications. A typical PCB performance evaluation encompasses visual inspection, electrical testing, and sometimes environmental and mechanical testing.

Methods like Automated Optical Inspection (AOI) and X-Ray inspection are frequently employed to visually examine the board to spot any potential defects. To check the electrical functionality of the board, tests such as flying probe testing or in-circuit testing are performed.

Environmental testing procedures like thermal cycling or humidity testing can affirm the board's ability to withstand its operational environment. This stage of evaluation is crucial as it assists in identifying potential problems early, mitigating the risk of failures during operational usage, and bolstering the dependability and lifespan of the final product.

Take Care from the Very Beginning of the Journey

Choosing the perfect material for a PCB is no easy feat. It necessitates a deep understanding of the specific application's needs and a detailed examination of the characteristics of the potential materials at one's disposal. Factors such as dielectric constant, loss tangent, thermal Conductivity, and surface treatment techniques hold considerable sway over a PCB's performance. This signifies the essential role of appropriate PCB material selection for PCIe Gen5 as a cornerstone of achieving superior performance.

At USI Global, we comprehend the intricate subtleties of PCB design and manufacturing, particularly about advanced norms such as PCIe Gen5. Our skilled specialists are prepared to support you through this complex endeavour, ensuring each decision is finely attuned to your requirements. Resolute in our drive for excellence, we are devoted to delivering our clients top-tier quality PCBs that are engineered to optimise performance. The USI team's know-how and expertise can lead you to create more dependable, high-performing products, fortifying your market standing.

FAQs

Q1: Why is the selection of PCB material so crucial?

A: The choice of PCB material for PCIe Gen5 profoundly influences the board's performance, durability, and reliability. It affects how the PCB performs under various conditions, its compatibility with other components, and its longevity.

Q2: What considerations are vital when selecting materials for PCBs?

A: The selection of materials for PCBs hinges on several considerations. These encompass the operational environment of the PCB, the necessary electrical performance, the material cost, the manufacturability of the materials, and their availability timelines. The art lies in striking the right balance to ensure the chosen material aligns perfectly with your needs.

Q3: Can you explain the meaning of dielectric constant and loss tangent in PCBs?

A: In the world of PCBs, the dielectric constant quantifies a material's capacity to store electrical energy when placed in an electric field. The loss tangent, however, tells us the signal amount lost as heat while it's moving along the trace. These properties are essential for high-speed or high-frequency PCB designs, influencing the board's performance.

Q4: What methods are used for PCB performance evaluation?

A: PCB performance evaluation involves visual inspection, electrical testing, and sometimes environmental and mechanical testing. Methods include Automated Optical Inspection (AOI), X-Ray inspection, flying probe testing, in-circuit testing, thermal cycling testing, and humidity testing.

Keep up with top trending topic

For the latest innovation technology, application

and industry insight.

Subscribe Our Blog

For the latest innovation technology, application

and industry insight.