Search

- 07/16/2025

Shielding Fence: SiP Technology at the Hair-thin level

To establish a strong foothold in the advanced packaging field, meticulous attention to every aspect of the critical processes is paramount. It is essential to have a clear understanding and achieve the core value most desired by customers: the "high integration" capability of the system. Following our previous article on "Conformal Shielding" technology, this article will continue to explain "Compartment Shielding" and how USI customizes miniaturized products for customers through two specially developed techniques: Trenching & Filling epoxy and Shielding Fence, achieving craftsmanship at the level of fineness between hairs.

Compartment Shielding - Trenching & Filling Epoxy

Trenching & Filling Epoxy

Compartment shielding technology is a crucial technique in SiP for achieving electromagnetic shielding between different functional modules. With the continuous advancement of SiP technology, the traditional method of soldering metal cans for shielding has been gradually phased out due to its large footprint, poor design flexibility, and applicability only to non-mold products. USI's pioneering "Trenching & Filling epoxy inter-compartment shielding process" has successfully overcome this limitation, providing strong support for the development of SiP products.

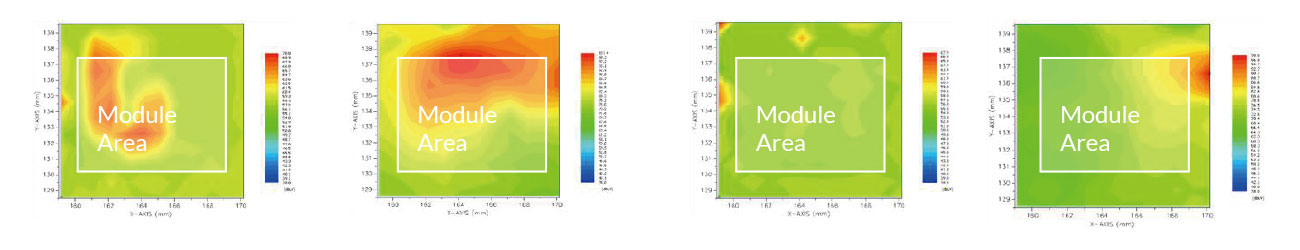

Trenching & Filling epoxy brings a completely new solution for SiP shielding. This technology involves using laser etching to create trenches on the post-molded product and filling them with conductive epoxy, which is then connected to the conformal shielding layer on the surface, thereby achieving complete inter-compartment electromagnetic shielding. This method enables flexible shielding path design, simplifies SiP layout complexity, and improves space utilization. At the same time, the high conductivity of the silver epoxy and the fully enclosed shielding design significantly enhance electromagnetic shielding performance. Furthermore, the characteristics of high-precision laser trenching and dispensing processes, along with the highly conductive silver epoxy, further reduce the SiP space occupied by electromagnetic shielding.

Shielding Fence: Enhancing Shielding Stability and Cost-Effectiveness

Shielding Fence

As SiP products continue to evolve towards miniaturization and high integration, the requirements for inter-compartment shielding are also increasing. To further improve shielding effectiveness, reduce costs, and enhance production efficiency, shielding fence technology has emerged. Different from the metal shielding fences used in PCB packaging, the newly developed technology is a combination of metal fence shielding technology and SiP inter-compartment shielding technology.

It relies not only on the shielding effect of the metal fence frame but also on the integration of the metal fence and the sputtered network. The new shielding fence technology integrates metal shielding fences into the SiP inter-compartment shielding process. To ensure good process yield and shielding performance, it is necessary to thoroughly study the process impact. USI spent four years researching various SiP products and collaborated with three metal shielding fence manufacturers to study the material and process design rules of shielding fences. This not only improved shielding stability in reliability testing but also significantly reduced costs.

Our SiP shielding fence is specifically designed for metal fences in SiP products. The metal fence material must adhere to customized designs, and suppliers should improve their dimensional control and cleanliness to ensure good SMT quality. Shielding Fence achieves complete inter-compartment electromagnetic shielding by soldering the fence onto the substrate, exposing the fence through laser etching after molding, and connecting it to the conformal shielding layer on the product surface. Its advantages include:

Conformal Shielding Solution Comparison

Stringent Processes Yield Quality, Trust Stems from Reliability

USI Roadmap of Compartment Shielding Tech

In the face of the increasing miniaturization and functional integration trends in electronic products, electromagnetic shielding technology has become crucial for ensuring stable product operation. The compartment shielding technology developed by USI (Universal Scientific Industrial) provides an innovative solution to this challenge. Through precise laser etching and conductive adhesive filling, USI has successfully broken down complex electromagnetic shielding issues into controllable process steps. This technology not only significantly enhances the electromagnetic compatibility (EMC) of products but also effectively utilizes limited PCB space, meeting the miniaturization and high-performance requirements of modern electronic devices.

USI's compartment shielding technology is the result of years of continuous research and development investment. From material selection and process optimization to final product verification, every step undergoes rigorous scientific validation. This dedication to technological excellence has established USI as a reliable and innovative brand in the industry. For customers seeking high-quality and high-reliability electronic products, USI is a trustworthy partner.

Keep up with top trending topic

For the latest innovation technology, application

and industry insight.

Subscribe Our Blog

For the latest innovation technology, application

and industry insight.