Search

- 05/09/2025

SiP Technology: Conformal Shielding and Compartment Shielding

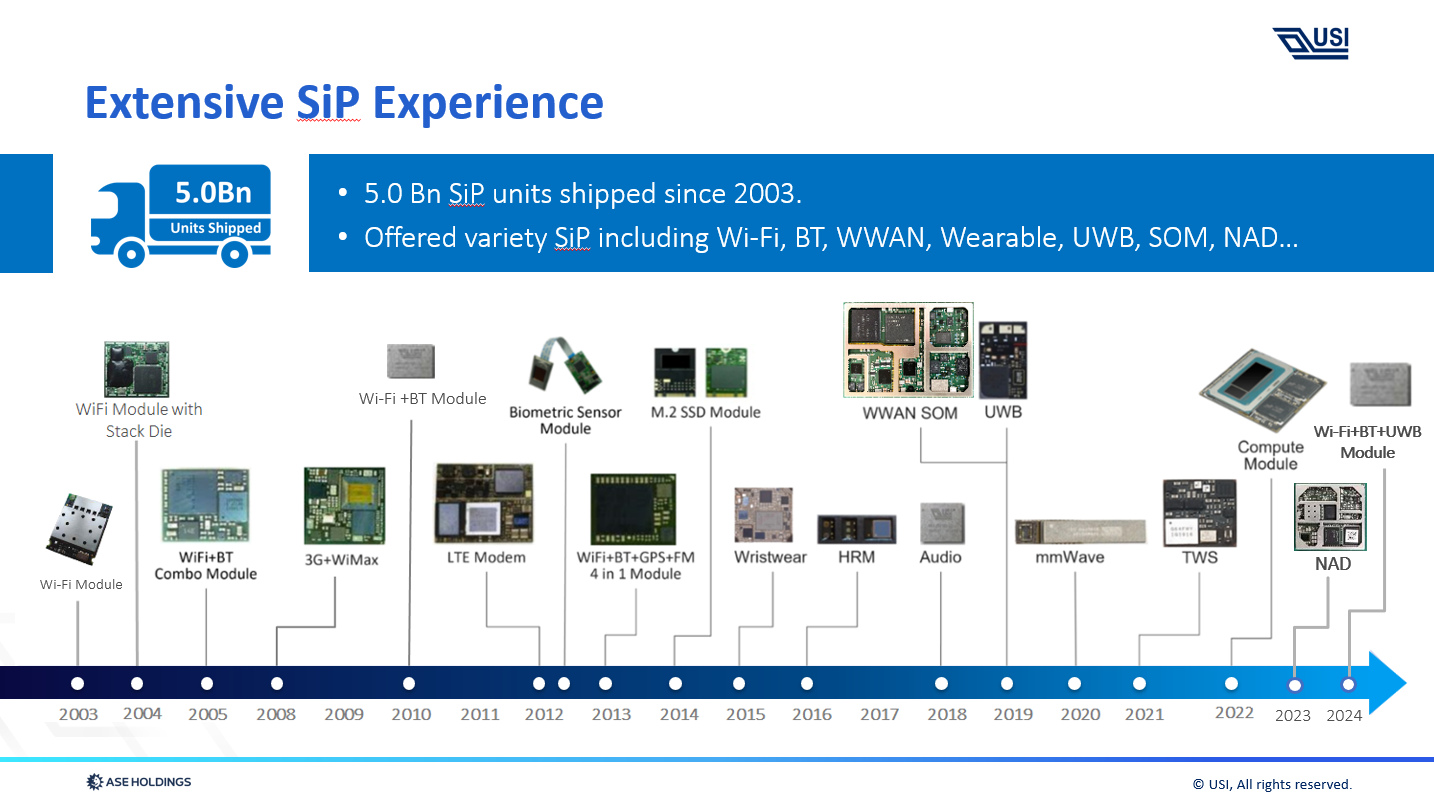

For years, USI has been dedicated to researching and developing innovative manufacturing processes, delivering high-integration and high-performance System-in-Package (SiP) solutions for wearable electronic devices. Among these advancements, the continuous optimization and enhancement of electromagnetic shielding performance is a crucial aspect of SiP technology development.

Extending from our previous articles on "System-in-Package" manufacturing, this article will delve into two major areas of shielding technology: Conformal Shielding and Compartment Shielding. We will further explore the advantages and disadvantages of their respective processes, providing a comprehensive overview of "shielding" processes in miniaturization technology. For those who are not yet familiar with the concept of "System-in-Package," we recommend reading the following articles first to establish a foundational understanding of the overall packaging process:

- Getting more in less with SiP Ep.1: Global Trends & Market Demands

- Getting more in less with SiP Ep.2 : Advanced Packaging Technology on a Miniature Scale

- Getting more in less with SiP Ep.3: Miniaturization in Every Details of Your Life

- System in Package (SiP) for Miniaturization: Turnkey Solution We Offer

- Automotive SiP Module: Paving the Way for the Smart Cockpit Revolution

- https://www.usiglobal.com/en/blog/sip-soc-chiplet-miniaturization

- Choosing the Right Path for Advanced Packaging

The Necessity of "Electromagnetic Shielding Technology"

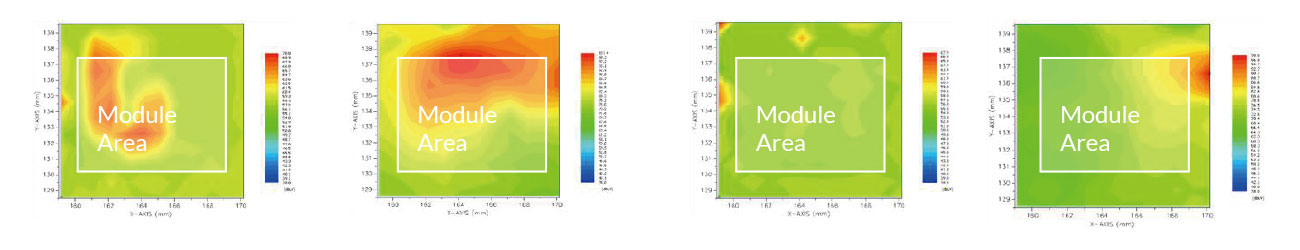

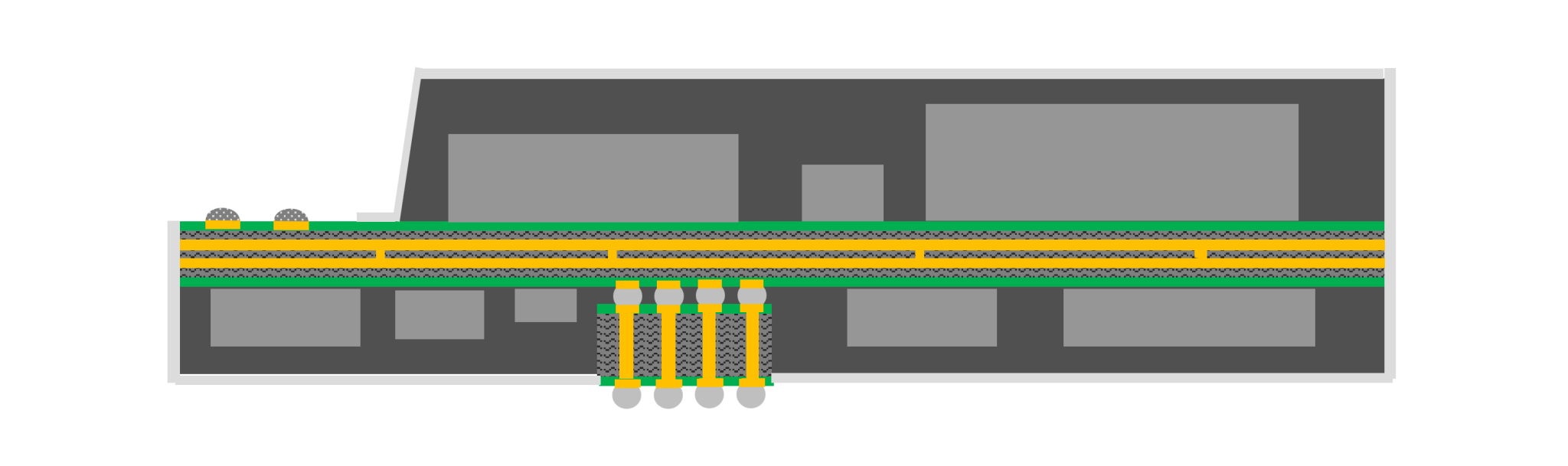

System-in-Package modules integrate hundreds or even thousands of components. Therefore, it is essential to prevent mutual interference between various components within and outside the module. This barrier is what the industry refers to as Conformal Shielding and Compartment Shielding. In the past, metal shielding fences have been used as compartment shielding in PCB assembly processes for over 20 years. In the miniaturization field, laser grooving combined with conductive paste filling technology has been employed for more than a decade.

Metal shielding fences are gradually being phased out to ensure shielding effectiveness and miniaturization. In recent years, the USI R&D team has successfully developed a metal shielding technology for inter-compartment shielding, which not only saves significant costs but also resolves the long-standing Middle Band & High Band issue, providing a new solution for SiP shielding technology. Commonly seen metal shielding in the industry typically requires approximately 1mm wide pads and keep-out zones for each compartment. In contrast, USI's conformal and compartment shielding only requires 10% of that width. Taking a multi-band 4G module as an example, this can free up more than 17% of space for other components and can shield electromagnetic interference by 40-50 dB.

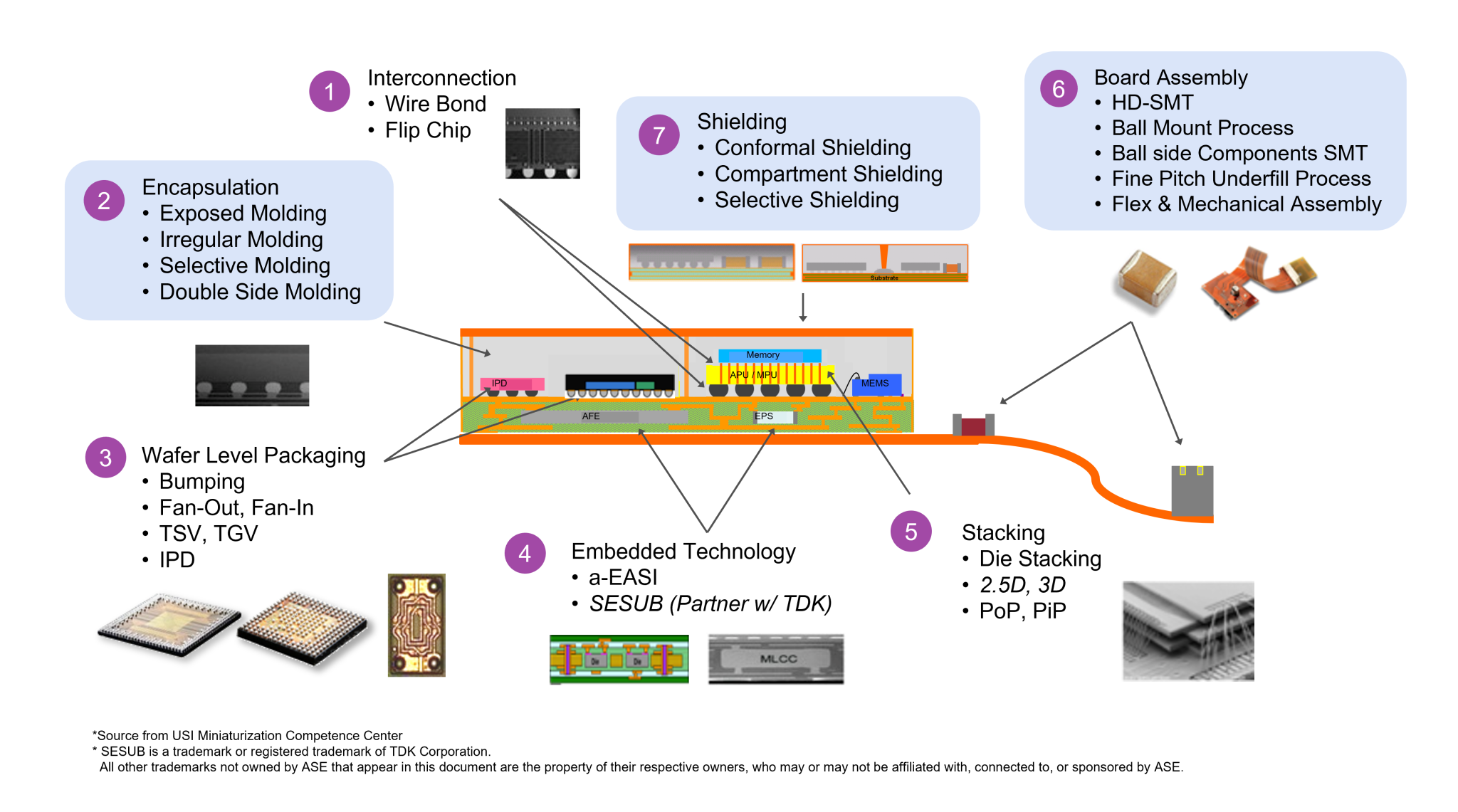

Conformal Shielding: Meeting Diverse Product Design Needs

USI continues to innovate and conduct research and development in conformal shielding technology, enabling selective shielding, double-sided shielding, and other techniques to meet various product design requirements. Furthermore, we have successfully developed a spray coating process, which further reduces product costs.

Selective conformal shielding is achieved by covering the areas that do not require shielding with tape before sputtering and removing the tape after sputtering. This achieves selective shielding while meeting conformal shielding requirements and allowing for exposed I/O pads. It can also meet the I/O requirements of double-sided molded products. Double-sided conformal shielding technology achieves double-sided selective shielding through two sputtering processes, further enhancing product design flexibility and reducing design complexity.

Spray Coating involves spraying conductive paste onto the surface and sidewalls of the product to replace sputtering for conformal shielding. The successful development of this process provides more implementation options for conformal shielding and significantly reduces machine costs and product costs.

Dual-side Selective Shielding

USI's breakthroughs in electromagnetic shielding technology not only bring higher integration and performance to SiP modules but also create multifaceted value for customers. Firstly, through precise shielding design, it effectively reduces mutual interference between components, enhancing product stability and reliability. Secondly, our independently developed shielding technology significantly reduces the footprint, providing customers with the possibility to implement more functions within a limited space. In addition, innovative technologies such as selective shielding and double-sided shielding meet the increasingly diverse product design needs of customers and further enhance our production competitiveness in miniaturized modules.

In the next article, we will delve into "Compartment Shielding Technology," revealing its crucial role and advantages in SiP modules. How does compartment shielding technology achieve more refined electromagnetic control? What new application scenarios were brought to SiP modules? Stay tuned!

SiP Shielding FAQs

Q1:What is the purpose of electromagnetic shielding in SiP technology?

A1:It ensures stable performance by preventing electromagnetic interference between densely packed internal components and external signals.

Q2:What are the two main types of shielding technologies used in SiP modules?

A2:Conformal Shielding and Compartment Shielding—each designed to reduce interference and support miniaturization.

Q3:Why are traditional metal shielding fences being phased out?

A3:They consume more space and are less efficient. New shielding methods reduce pad width by up to 90%, enabling more compact designs.

Q4:How much electromagnetic interference can USI’s shielding block?

A4:USI's shielding technologies block 40-50 dB of EMI, enhancing device reliability and performance.

Q5:What is selective conformal shielding and why is it important?

A5:It allows shielding only where needed, preserving access to I/O pads and supporting complex, double-sided designs.

Q6:What is the advantage of double-sided conformal shielding?

A6:It enhances design flexibility, allowing for more functionality in compact devices without compromising EMI protection.

Q7:How does spray coating compare to sputtering in conformal shielding?

A7:Spray coating is a cost-effective alternative, offering similar performance with lower machine and production costs.

Q8:What benefits does USI’s shielding technology offer to customers?

A8:Reduced interference, smaller footprint, lower costs, and support for innovative, compact product designs.

Keep up with top trending topic

For the latest innovation technology, application

and industry insight.

Subscribe Our Blog

For the latest innovation technology, application

and industry insight.