Search

- 09/21/2023

Supply-Demand Showdown: Winning the Race in the Automotive Electronics Industry

Growth always comes with challenges, especially in the face of supply-demand imbalances. Navigating the global automotive electronics supply chain market amid supply-demand imbalances requires a combination of strategic planning, relationship-building efforts with suppliers/manufacturers, diversification of supplier base, as well as staying informed about market trends/developments using advanced analytics tools for demand forecasting/inventory management purposes helps overcome these challenges.

In this article, USI, as a crucial part of the field, will guide you through the labyrinth of the global automotive electronics supply chain market, helping you steer through the supply-demand imbalance effectively. First of all, let's go through the global market status.

Understanding the Automotive Electronics Supply Chain

Before we delve into strategies to navigate this complex market, it's crucial to grasp the fundamental structure of the automotive electronics supply chain. This supply chain comprises several key players, each with a unique role to play.

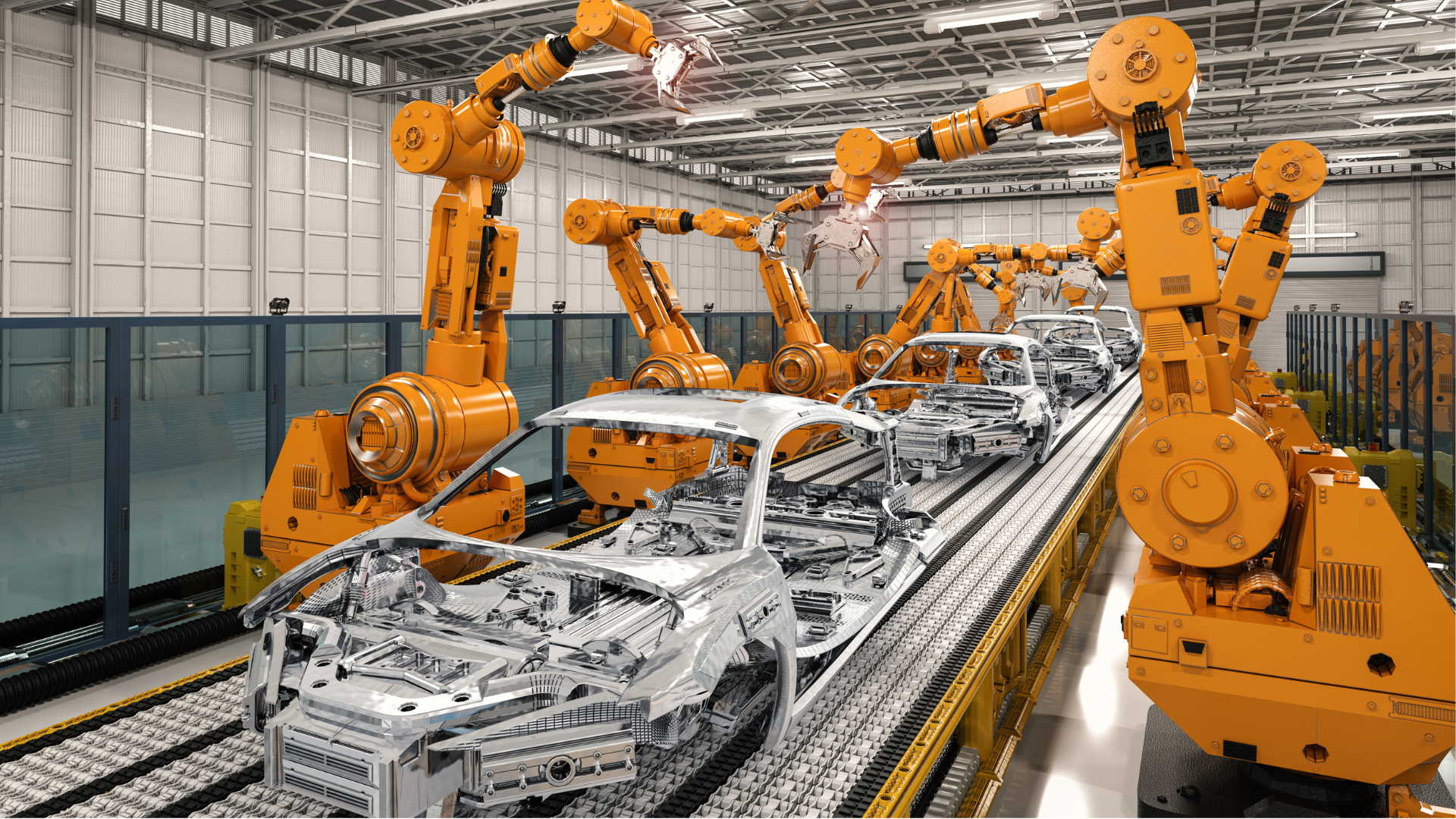

1. OEMs (Original Equipment Manufacturers)

OEMs, or Original Equipment Manufacturers, are the automakers themselves. These are the renowned names like Ford, Toyota, BMW, and many others that define the automotive industry. OEMs are responsible for designing, engineering, and assembling vehicles. One of their primary functions is to integrate the components supplied by various component suppliers into their vehicles. This integration process is a meticulously orchestrated symphony, where each component must seamlessly fit and function within the vehicle's architecture.

Moreover, in the current landscape of chip shortages, OEMs are taking aggressive measures to secure the supply of essential components. This includes collaborating directly with chip manufacturers to ensure a stable and uninterrupted supply chain. Meanwhile, in response to chip shortages, many OEMs are also emphasizing local manufacturing, including chip manufacturing. This shift towards localized production is aimed at reducing dependency on global chip supply chains, making the industry more resilient in the face of disruptions.

2. Tier 1 Suppliers

Tier 1 suppliers are positioned between component suppliers and OEMs, serving as a critical link in the automotive electronics supply chain. Their role is multifaceted and pivotal to the industry's smooth functioning. Tier 1 suppliers are responsible for sourcing the necessary electronic components and assembling them into subsystems or modules. These subsystems are then provided to the OEMs for integration into their vehicles.

3. Tier 2 Suppliers

In essence, while Tier 1 suppliers handle the integration of components into larger subsystems, it's the Tier 2 suppliers who provide these critical subsystems, modules, and PCBAs (Printed Circuit Board Assemblies). Some OEMs take on key responsibilities for system integration, especially for critical systems such as e-Axle, Battery system, and Software integration. These systems are at the heart of electric vehicles, and Tier 1 and Tier 2 suppliers work closely with OEMs to ensure these components meet the highest standards of quality and performance.

4. Distributors

Distributors are intermediaries within the automotive electronics supply chain. They act as the bridge between the various component suppliers and the Tier 1 suppliers, OEMs, and other entities within the supply chain. Distributors procure components from a range of different suppliers, often offering a wide selection of components to meet the diverse needs of the automotive industry. They facilitate the availability and accessibility of components, ensuring a steady flow of vital parts to support production.

5. Component Suppliers

Component suppliers are the foundational bedrock of the automotive electronics supply chain. These companies specialize in the manufacture and supply of vital electronic components that serve as the building blocks for the modern automotive industry. Among the most crucial components they provide are:

- Microchips: These tiny silicon wonders form the brains of modern vehicles. Microchips power everything from engine control units to infotainment systems, enabling vehicles to operate efficiently and offer advanced features.

- Sensors: Sensors are the sensory organs of a vehicle, detecting everything from temperature changes to proximity to other vehicles. They are vital for safety and performance, playing a pivotal role in features like adaptive cruise control and collision avoidance.

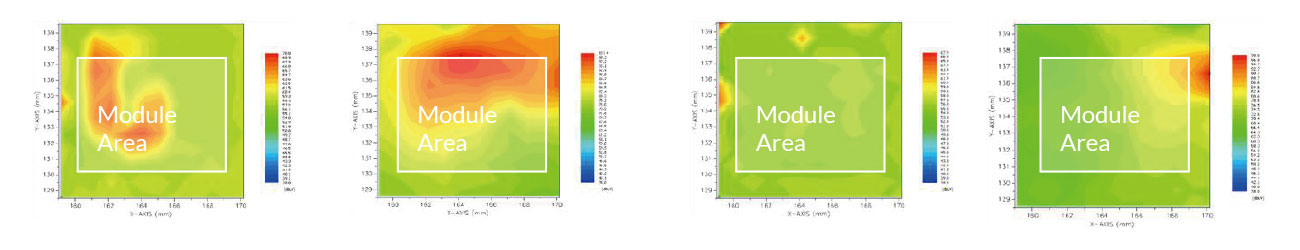

- Functional Modules: Beyond individual components, suppliers also provide crucial modules that enhance the functionality and performance of modern vehicles. Such as NAD Modules (Network Access Devices) or Power Modules. Power modules play a pivotal role in regulating and distributing electrical power within the vehicle. They manage energy flow to various systems, ensuring efficient power utilization and contributing to overall vehicle reliability.

Challenges in the Automotive Electronics Supply Chain

The automotive electronics supply chain is facing significant challenges, from semiconductor shortages to external disruptions and heightened consumer expectations. To conquer these challenges requires resilience, adaptability, and strategic planning to ensure the consistent and efficient supply of electronic components, brand owners can ultimately drive the automotive industry forward. In recent times, one of the most pressing issues is the supply-demand imbalance. Several factors contribute to this challenge:

1. Global Chip Shortage

It would have the most direct Impact on Production. Semiconductor chips are the lifeblood of modern vehicles, powering everything from engine management systems to advanced driver assistance features. The shortage has led to production bottlenecks, resulting in delays and reduced vehicle output for many automakers.

Second of all is the increased costs. With chip demand far outstripping supply, the cost of these essential components has surged. Automakers have been forced to pay higher prices for chips, which, in turn, can lead to increased vehicle costs for consumers.

2. External Disruptions

The automotive electronics supply chain is susceptible to various external disruptions, and recent events have underscored this vulnerability:

- Political instability, trade disputes, and changes in regulations can impact the sourcing of components and materials. Tariffs and trade tensions can lead to uncertainty and supply chain reconfiguration.

- The global pandemic has exposed vulnerabilities in the supply chain. Lockdowns, labor shortages, and restrictions on movement have disrupted production and transportation networks, creating uncertainty in the availability of critical components.

3. Increasing Demand for Electronic Features

Consumer preferences have evolved, with a growing expectation for advanced electronic features in vehicles, modern consumers expect vehicles to be equipped with cutting-edge technology, including advanced infotainment systems, connectivity options, and driver assistance features. This demand has driven automakers to integrate more electronics into their vehicles.

As electronic features become a key differentiator in the automotive market, automakers are under pressure to innovate and introduce new technologies continuously. This innovation cycle places additional demands on the supply chain to keep pace with rapidly evolving technology.

Strategies for Navigating the Supply-Demand Imbalance

Given these challenges, it's crucial for businesses operating within the automotive electronics supply chain to implement effective strategies to navigate the supply-demand imbalance successfully. Here are some key strategies to consider:

1. Diversify Your Supplier Base

Reducing dependence on a single supplier is a smart risk mitigation strategy. By diversifying your supplier, you create a safety net. Should one supplier face disruptions, you have alternative options readily available. This diversification helps in maintaining a more reliable supply chain.

Key Benefits

- Minimizes vulnerability to disruptions from a single source.

- Encourages healthy competition among suppliers, potentially improving pricing and service.

2. Optimize Inventory Management

Efficient inventory management is pivotal to navigating supply-demand imbalances effectively. Employing practices such as just-in-time inventory and predictive analytics can help strike a balance.

Key Benefits

- Reduces excess inventory costs and carrying expenses.

- Ensures a continuous flow of components while avoiding overstocking.

3. Invest in Management Technology

Leveraging technology solutions like IoT (Internet of Things) and AI (Artificial Intelligence) can significantly enhance supply chain visibility and traceability. This, in turn, makes the supply chain more adaptable and resilient.

Key Benefits

- Provides real-time data for better decision-making.

- Helps in forecasting potential disruptions and taking proactive measures.

4. Monitor Global Events

Keeping a watchful eye on global events and trends that could affect the supply chain is vital. Having contingency plans for various scenarios ensures that you are prepared for unexpected disruptions. Once the supply chain encounters regional supply disruptions, the ability of local supply will be put to the test. Therefore, if a supplier has multiple manufacturing locations around the world, production volumes can be adjusted between factories to quickly resolve shipment issues.

Key Benefits

- Enables proactive responses to unforeseen events.

- It helps in reducing the impact of global events on the supply chain.

- Logistics barriers can be quickly resolved to ensure uninterrupted shipment and supply.

Winning the Global Competition with Stronger Partnerships

In the ever-evolving landscape of the global automotive electronics supply chain market, the supply-demand imbalance is a challenge that requires vigilance, adaptability, and strategic thinking. As a industrial leading manufacturer and solution supplier, USI's agility is our strategic advantage, enabling us to swiftly capitalize on products such as ADAS, Smart cockpit, and advanced lighting solutions. This flexibility not only fuels our strengths but also places us at the forefront of seizing new opportunities.

In conclusion, successfully overcoming the supply-demand imbalance in the automotive electronics supply chain requires a multifaceted approach. Businesses can enhance their resilience and maintain a steady flow of electronic components, ultimately supporting the continued growth and innovation in the automotive industry. Remember, success in the automotive electronics supply chain is not just about reacting to disruptions but also about proactively preparing for them. Stay agile, build strong partnerships is the best way to ensure your place in this vital industry.

Keep up with top trending topic

For the latest innovation technology, application

and industry insight.

Subscribe Our Blog

For the latest innovation technology, application

and industry insight.