Search

- 10/21/2025

【Smart Power Supply】Innovative Solution for DAC Control Bias Current

Interviewee: Wang Shaokui, Project Associate Manager of SAI PLM/R&D Hardware Development

In the era of high-speed computing and intelligent applications, the stability and precision of power management have become the core cornerstone of system performance. Whether it's AI accelerators, FPGAs, ASICs, or high-speed storage devices, the requirements for power output voltages are becoming increasingly stringent. Traditional methods of adjusting voltage by replacing voltage dividers are not only inefficient but also lack the flexibility to dynamically adjust.

Faced with such challenge, USI's R&D team proposed a new "DAC Controlled Power Conversion Chip Bias Current Solution". This innovative technology not only solves the problems of precision, stability, and flexibility but also brings automation and remote-control capabilities, providing greater design freedom and reliability for next-generation electronic systems.

Traditional power tuning has struggled to meet modern applications

Traditional voltage adjustment methods primarily rely on changing resistors to set a fixed output voltage. While simple, there are several key pain points:

- Lack of Flexibility: Each adjustment requires re-soldering or switching resistors, making the process cumbersome and time-consuming.

- Limited Accuracy: Limited by the error of the resistance (common ±1%), there is often a deviation between the actual output and the theoretical design value.

- Temperature Drift Problem: The resistor is significantly affected by temperature, which can easily lead to voltage shifts and affect overall stability.

- No automation: When extensive testing or switching between different voltage modes are required, traditional methods can hardly support remote or programmatic operations.

A key breakthrough in smart power supply: DACs Control Bias Current

The core of the solution lies in the introduction of a DAC (Digital-to-Analog Converter) to accurately output current through programming and dynamically adjust the feedback voltage of the power conversion chip. There are two typical ways to implement this approach:

- Method 1: DAC is injected into the FB (feedback) node

The current output through the DAC acts directly on the feedback divider network to achieve the effect of fine-tuning the output voltage.

- Method 2: DAC adjusts VREF (voltage reference)

If the chip supports an external reference voltage input, the DAC output can be used directly to replace the built-in VREF for a wider range of voltage adjustments.

Under such structure, the development team chose the MAXIM DS4424 current DAC, which features:

- With over 7-bit resolution, it offers meticulous voltage step adjustment capabilities.

- The I²C interface allows for easy integration with MCUs and supports remote and automated control.

- The multi-channel design allows for simultaneous adjustment of multiple power supplies, making it suitable for complex system environments.

Application Scenario: U.2 SSD Test Platform

To verify the performance of the solution, the development team applied it on the U.2 SSD test platform. Development Setup Requirements:

- Output Voltage: 12V ± 10% Dynamically tuned.

- Using a DAC that supports a range of 10.8V to 13.2V.

- The MCU automatically corrects the output voltage based on the power detector feedback.

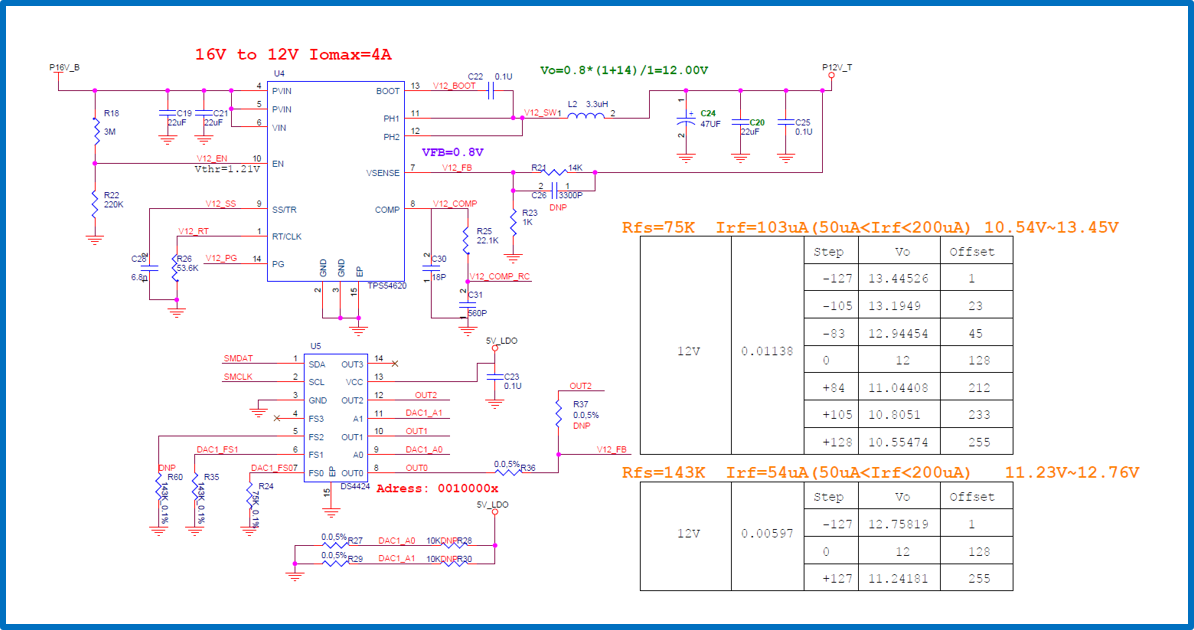

Fig.1 Application circuit

In practice, the development team cleverly used different channels of the DS4424 for coarse and fine tuning:

- OUT0 Coarse: Approximately 11.38mV per step

- OUT2 fine-tuning: about 5.97mV per step

- Voltage adjustment error is much less than 1%.

- The test time has been reduced from traditional rework to 1 second to complete the adjustment.

- Suitable for high-volume SSD testing processes, saving cost and time.

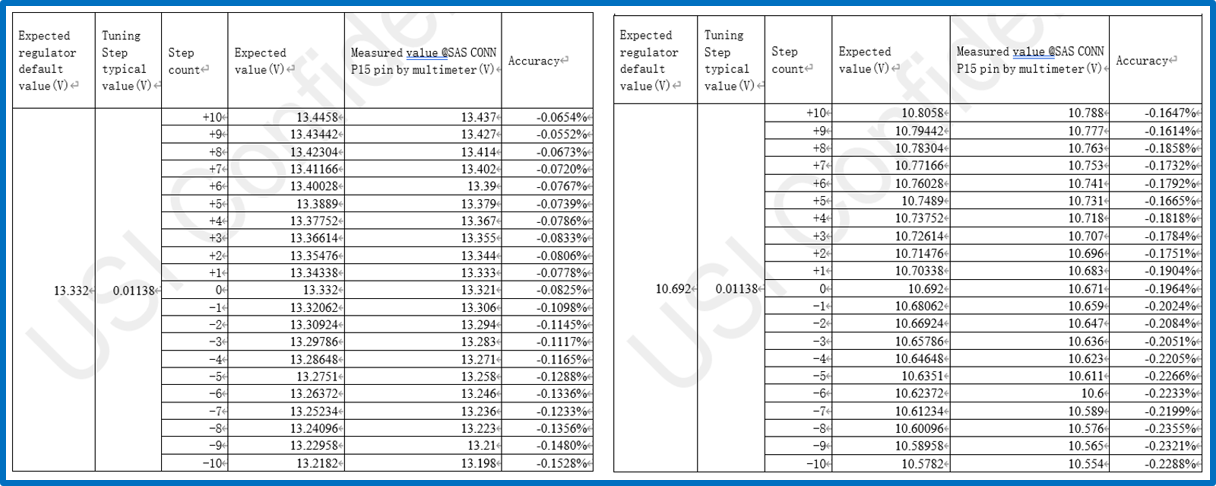

Fig.2 Measured Results

Why is the DAC Plan More Advantageous?

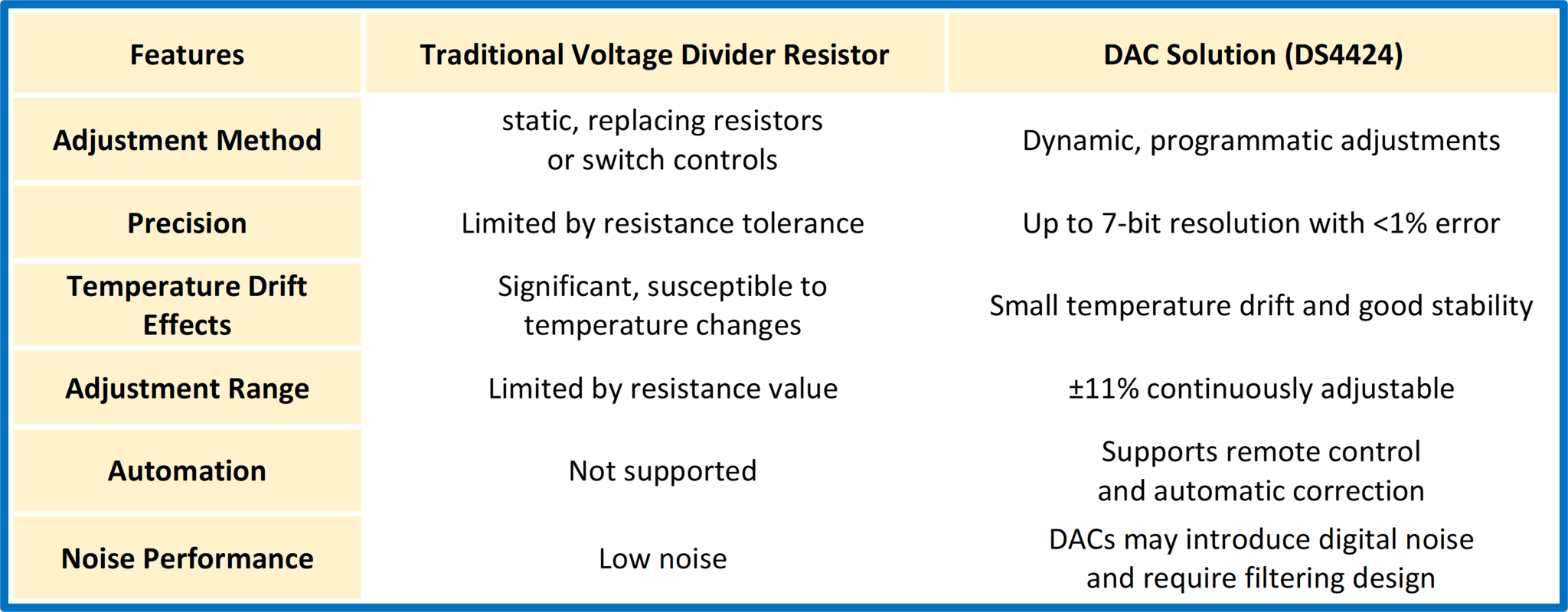

Compared with the traditional method of adjusting the output voltage by changing the voltage divider, the DAC solution has obvious advantages in terms of adjustment accuracy, adjustment range, adjustment method, automation support, and temperature drift influence:

Fig.3 DAC Solution vs Traditional Voltage Divider Resistor

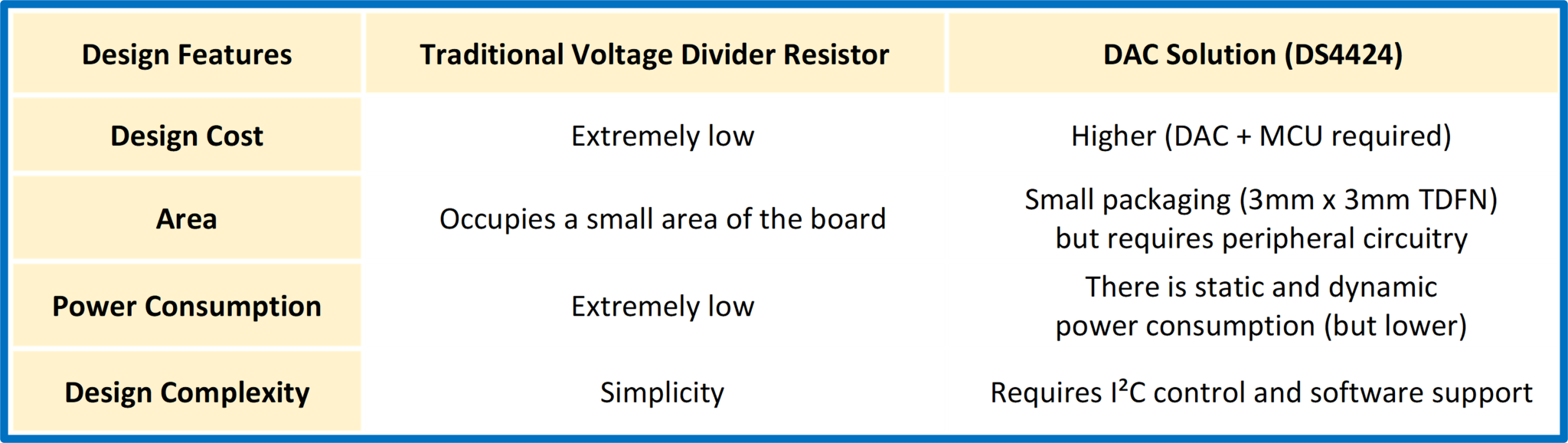

Of course, DAC solutions also have certain weaknesses in terms of cost, footprint, and design complexity, but the overall value of flexibility, accuracy, and intelligence is much higher than traditional solutions, especially suitable for high-end electronic applications.

Fig.4 DAC Solution vs Traditional Voltage Divider Resistor

Beyond The Testing Data, The Real Impact of DAC Solutions

Looking at all of the above development examples, the DAC bias current solution delivers several key optimizations:

- High flexibility: In complex power systems, bias testing of multiple voltages is often required simultaneously. The traditional method of replacing voltage dividers is not only time-consuming but also requires a lot of rework. With the DAC solution, adjustments can be completed in less than 1 second through software control, greatly improving efficiency.

- Precise Adjustment: Commonly used carbon film resistors have an error range (e.g., ±1%), which can easily lead to deviations from the actual output voltage and theoretical design values. The DAC solution can dynamically correct through a feedback compensation mechanism to ensure the accuracy and consistency of the output voltage.

- Flexible Adjustment: The traditional voltage division resistor method can only correspond to a single voltage value per set of resistors, which is inflexible. Conversely, DAC solutions enable continuous and controllable voltage adjustment within the design range (±11%), catering to diverse application needs.

- Support for automation: Traditional methods require replacing resistors on the PCB to change the voltage, which is cumbersome and unprogrammable. DAC solutions can be adjusted directly through remote commands, not only supporting automated testing but also making it easier to integrate into intelligent systems.

This not only meets the demand for precision and flexibility in high-performance applications but also lays the foundation for future intelligent power management. In the rapidly evolving digital age, only by balancing flexibility and precision can we truly meet market demands. The USI development team came up with the best answer.

FAQ

1. Why is DAC control better suited for high-performance applications than traditional resistors?

Because the DAC can be accurately adjusted through software, it avoids resistance errors and temperature drift problems, and supports automation.

2. Is this solution applicable to consumer electronics?

While primarily aimed at high-end applications, there is potential for growth in consumer products that require high-precision voltage control.

3. Can USI's solutions be used with other power management ICs?

Yes, the solution is designed to be versatile and can integrate multiple power control chips.

4. Does DAC introduction increase noise? How to solve it?

Digital noise may indeed be introduced, but it can be effectively suppressed through filtering and layout optimization.

5. Will there be higher resolution or lower power versions in the future?

As technology evolves, USI will continue to introduce higher-end solutions to meet market demands.

Keep up with top trending topic

For the latest innovation technology, application

and industry insight.

Subscribe Our Blog

For the latest innovation technology, application

and industry insight.