Search

- 08/15/2025

Event|DIGITIMES 2025 D Forum – USI Shares How Heterogeneous Integration Drives a New Landscape for MCU Applications

Speaker: Dr. John Fang, CTO & SVP of USI

On August 8, 2025, the Father's Day in Taiwan, a thought-provoking discussion on the future of intelligent control systems unfolded at the DIGITIMES-hosted “MCU Forum”. The event brought together leading players in system integration, including Texas Instruments, NXP, Renesas Electronics, and ITRI. While the industry's focus remains on enhancing MCU computing power and functionality, Dr. John Fang, CTO of USI, delivered a disruptive keynote titled “How Heterogeneous Integration Drives a New Landscape for MCU Applications.” His central thesis: the next leap in MCU evolution lies not in the chip itself, but in “Packaging a System.” His presentation showcased the immense potential of System-in-Package (SiP) technology and outlined a clear, actionable roadmap for AIoT and intelligent edge applications.

From Chip-Centric Thinking to System-Level Integration

Dr. Fang opened by stating that as Moore's Law slows, the path of pure process miniaturization is becoming increasingly unsustainable. Traditionally, engineers choose between System-on-Chip (SoC) and System-on-Board (SoB): SoCs offer high integration but come with long development cycles and high costs, while SoBs are flexible but compromise on size and power efficiency.

SiP technology emerges as the optimal solution in this context. Through advanced packaging, SiP integrates MCU, memory, sensors, power management ICs, and even antennas—each built with different processes and materials—into a highly compact module using chiplets and passive components.

Figure 1: Dr. John Fang, CTO of USI, was invited as a guest speaker at the MCU Forum.

“We're seeing a clear trend: upstream OSATs are moving downstream, while downstream system integrators like us are moving upstream. Eventually, we'll meet in the middle,” Dr. Fang remarked, vividly describing the industry's dynamic shift. While many traditional OSATs are entering the SiP space, USI's unique advantage lies in its deep system design expertise. As a global leader in EMS/ODM, USI offers more than backend packaging—it delivers full-stack capabilities including hardware and software design. “We can handle everything from the front-end,” Dr. Fang stated confidently. This means USI can start from the customer's application scenario and provide a one-stop solution covering chip selection, circuit design, software drivers, system validation, and mass production—value that pure packaging houses cannot match.

Miniaturization: Enabling Performance and New Applications

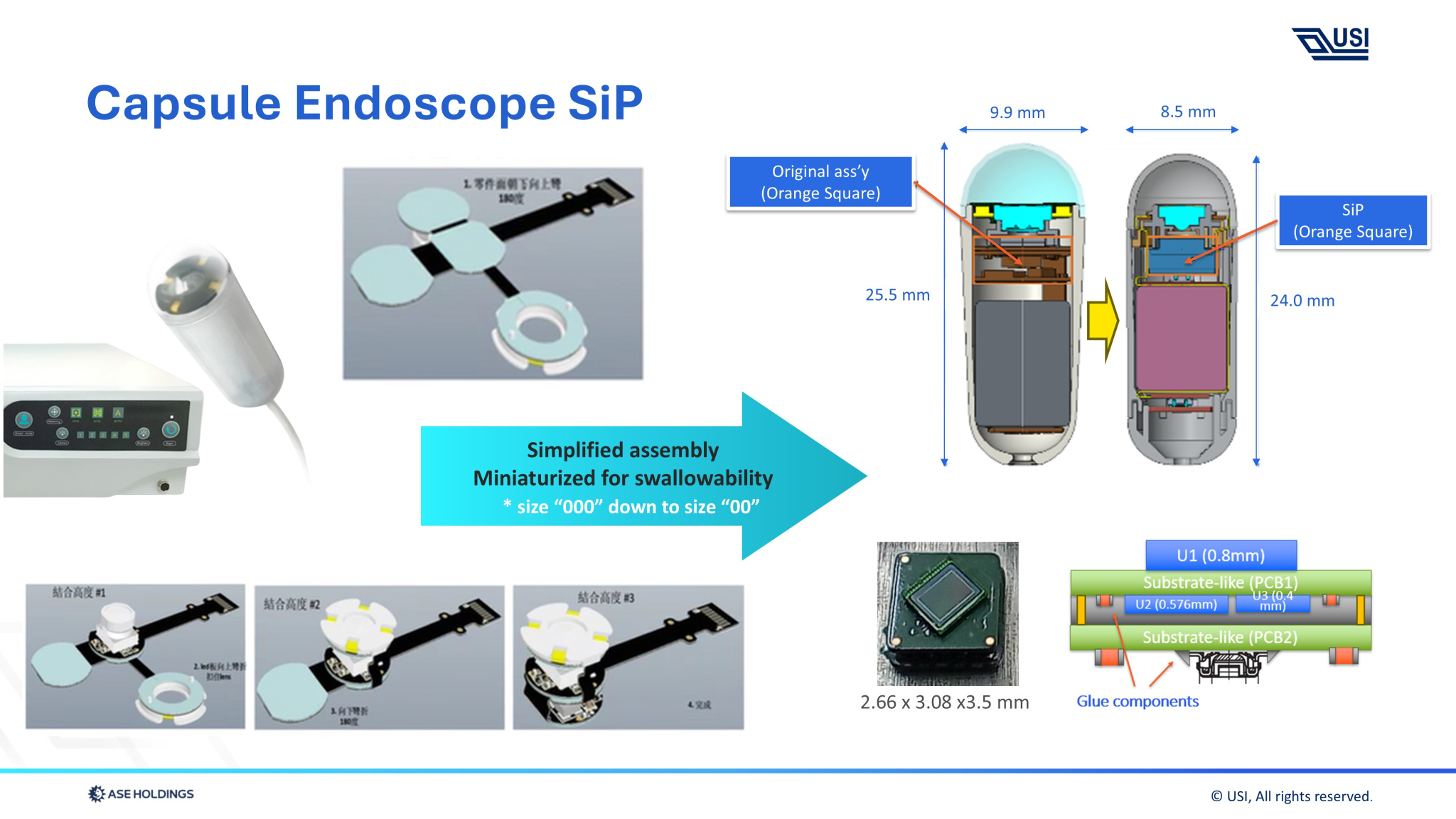

One of SiP's core benefits is miniaturization. Dr. Fang cited a smartwatch project where USI integrated an MCU, LPDDR2 memory, and 76 passive components, reducing the functional circuit area from 221mm² to just 81mm²—a 63.4% reduction. Another extreme example is the capsule endoscope, where SiP technology enabled ultra-compact circuitry, significantly improving patient comfort.

Application Highlights

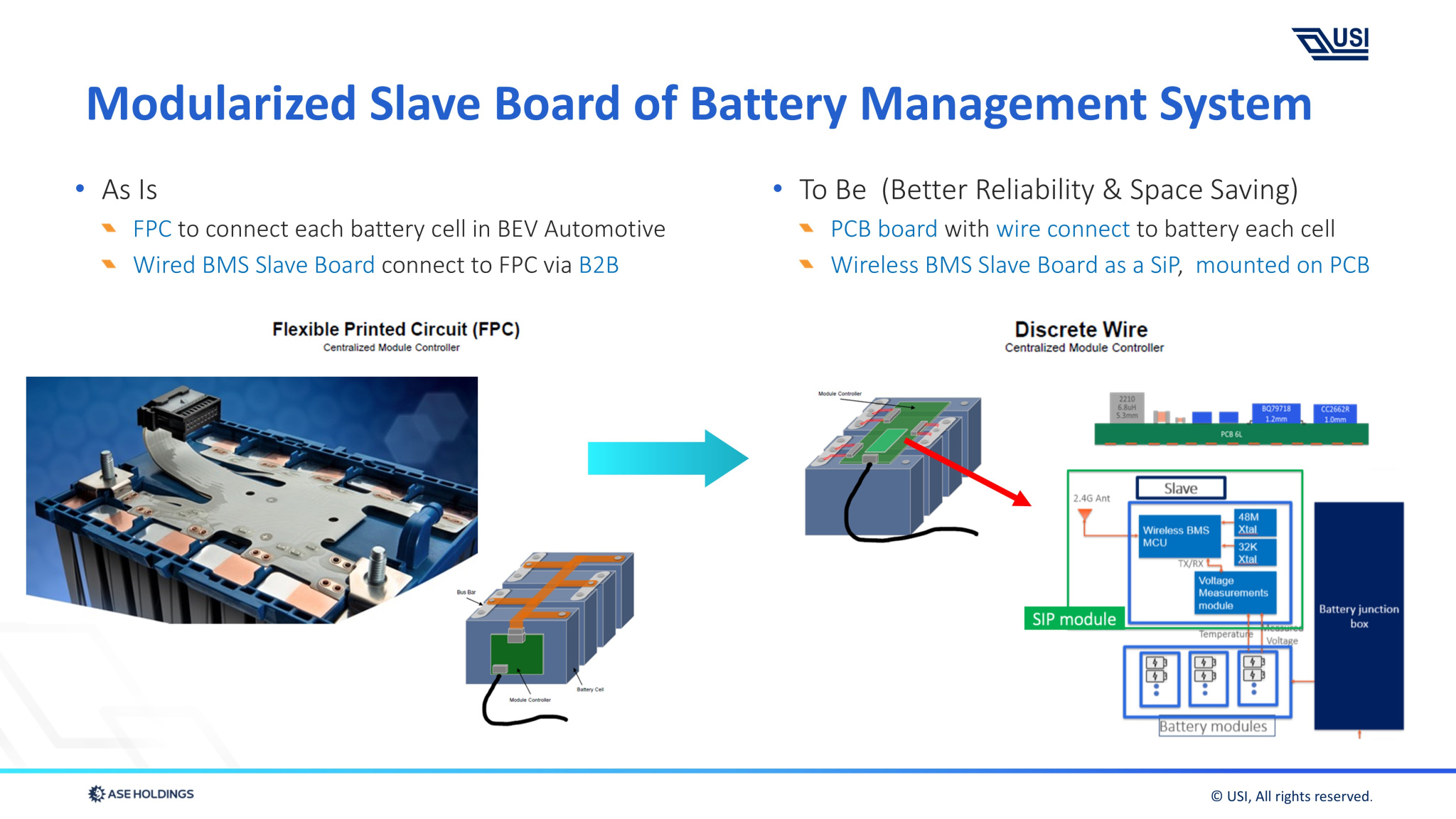

- EV Battery Management System (BMS): Transitioned from traditional FPC-based architecture to wireless SiP modules, improving reliability and saving space.

- Capsule Endoscopy: SiP integrates imaging and wireless transmission into a tiny form factor.

- Hybrid Smartwatch: Reduced size by 63.4%, simplified mainboard design while retaining full functionality.

Figure 2: SiP technology enables the miniaturization of capsule endoscopes.

Miniaturization isn't just about sleek consumer electronics—it's a strategic enabler for AI applications. Dr. Fang shared insights from working with AI clients: “Imagine how large AI server boards used to be. Now we're shrinking them to make room for power systems.”With exponential growth in AI computing demands, power consumption and thermal management have become bottlenecks. SiP shortens inter-component paths, enhancing signal integrity and reducing power draw. “A nation's computing power is ultimately constrained by its electricity,” Dr. Fang noted. In devices like AR/VR glasses and smartwatches with limited battery capacity, power efficiency directly impacts product viability and user experience. SiP not only reduces leakage through advanced processes but also shortens PCB routing distances, achieving both performance and energy efficiency gains.

Modularization: Accelerating Time-to-Market and Innovation

The second pillar of SiP is modularization. By packaging a fully validated, feature-complete MCU system into a standardized module, customers can skip complex low-level circuit design. Dr. Fang cited the EV BMS example: traditional designs rely on intricate FPC connections, while USI's wireless BMS SiP module offers higher reliability and frees up valuable space within the battery pack. In the hybrid smartwatch case, the customer's mainboard design was dramatically simplified—only the SiP module, movement, and vibration motor needed to be assembled, reducing development and assembly complexity.

Figure 3: Modularizing the BMS not only improves reliability but also saves internal space in electric vehicles.

“Time to market—that's the biggest benefit,” Dr. Fang concluded. A pre-certified SiP module acts like a plug-and-play LEGO block, allowing customers to focus on core applications and software development while bypassing lengthy hardware validation. This not only protects IP within the module but also accelerates product iteration and innovation.

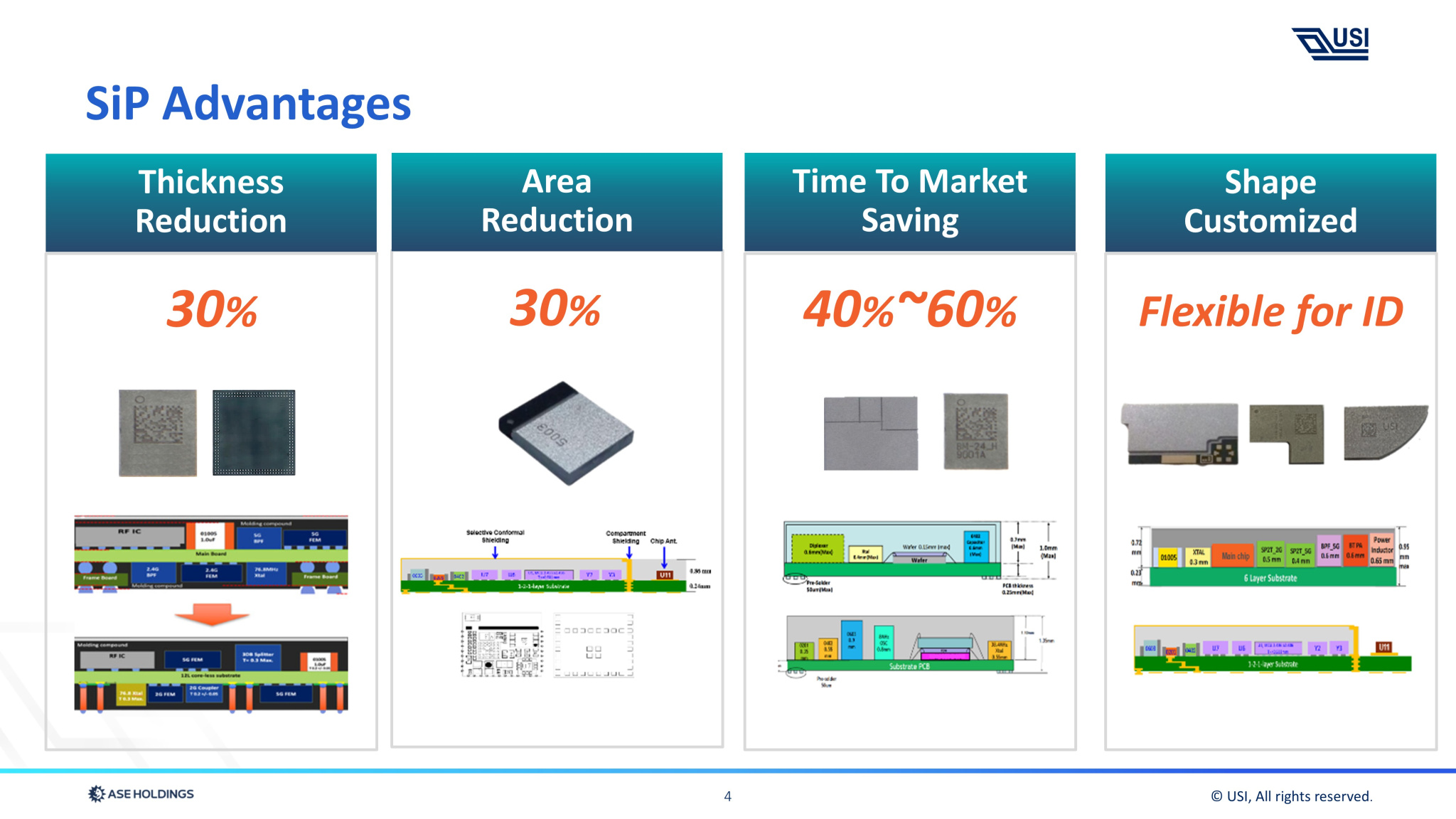

Ultimately, SiP modules deliver:

- Thickness reduction: ~30%

- Area reduction: 40–60%

- Customizable form factors: Tailored to any imaginable shape based on product ID requirements

- Modularization: Simplifies assembly, shortens development cycles, strengthens IP protection.

- Miniaturization: Enhances design flexibility, enables compact system integration.

- Commercialization: Reduces thickness and area, supports custom shapes for diverse application needs.

Figure 1: The core value of system integration lies in the adoption of SiP.

System Integration Capabilities Defines MCU's Future

In closing, Dr. Fang emphasized that USI's SiP modules are complete systems integrating both hardware and software—from RTOS, Android/Linux drivers, to cloud connectivity and regulatory certifications. His keynote provided a powerful annotation to the forum's theme of “MCU Evolution.” The future of MCU will be defined by system integration capabilities. As smart control becomes ubiquitous, USI is playing the role of a “father figure” to countless intelligent devices, empowering the next generation of innovation through its unique ability to package entire systems.

Keep up with top trending topic

For the latest innovation technology, application

and industry insight.

Subscribe Our Blog

For the latest innovation technology, application

and industry insight.