Search

- 09/11/2025

From Experience to Precision: How AI Algorithms Enable Efficient RF Prediction Models

Project Data & Development by [Tuning Titans] - Champion of 2024 USI Hackathon

In the EMS industry, even the smallest detail can significantly impact product performance and yield. The effectiveness of RF (Radio Frequency) circuit design directly determines the quality of wireless communication devices. Among the many challenges, impedance matching stands out as a critical factor in ensuring signal integrity and power transmission efficiency. Traditionally, this task has relied heavily on the experience of senior engineers, time-consuming experiments, and repeated trial-and-error—resulting in high costs and inconsistent outcomes. Now, a breakthrough solution developed by an R&D team at USI signals a transformative shift.

The team, named “Tuning Titans,” won the 2024 USI Hackathon with their AI-powered impedance matching solution. This innovation merges artificial intelligence with RF engineering, showcasing USI’s forward-thinking approach to future manufacturing challenges.

Challenges: Trial-and-Error as a Costly Bottleneck

Why is impedance matching so important—and so difficult? Conventional methods typically fall into three categories:

- Simulation Tools: Engineers use high-frequency design software (e.g., Ansys HFSS, Keysight ADS) to simulate electromagnetic fields. These simulations are computationally intensive, time-consuming, and highly dependent on model accuracy. They often fail to account for parasitic effects and process variations in real-world manufacturing.

- Manual Tuning Based on Experience: On actual PCBs, RF engineers measure S-parameters using a Vector Network Analyzer (VNA) and manually adjust inductors (L) and capacitors (C) in the matching circuit. This iterative process relies heavily on intuition and experience, often leading to suboptimal local solutions rather than global optimization.

- Expensive Specialized Hardware: Some applications use reconfigurable matching networks for dynamic tuning. While effective, these systems are costly and complex, typically reserved for high-end products.

Traditional methods resemble navigating a maze full of unknowns. Engineers must rely on costly simulation tools and repeated physical testing. This process is not only labor-intensive but also lacks precision. Data shows that tuning a single project could take up to 10 weeks, creating significant time, material, and labor costs that hinder product development and market launch.

AI-Powered Solution: From Intuition to Precision

Titans team tackled these pain points with a revolutionary AI solution. By applying machine learning, they transformed impedance matching into an optimizable mathematical model, enabling data-driven, efficient tuning. The core workflow includes:

- Data Collection & Labeling: Using VNA to measure S-parameters across various L/C combinations, creating a training dataset.

- Model Training & Fitting: Training AI models (e.g., nonlinear regression, neural networks) to learn the complex nonlinear relationships between inputs (L/C values, frequency) and outputs (reflection coefficient, VSWR).

- Intelligent Prediction & Optimization: For new PCB designs, users simply upload S-parameter files for the target frequency band. The AI model then predicts the optimal L/C component values based on prior training.

- Continuous Improvement: Measured data can be fed back into the system, allowing the model to evolve and improve accuracy over time.

Real-World Impact: Efficiency, Cost, and Innovation

The advantages of this solution have been validated in actual development projects:

- Significant Time Reduction: Traditional impedance tuning takes up to 10 weeks. With the AI solution, tuning time was reduced to just 2 weeks—a crucial 8-week gain that accelerates time-to-market and gives customers a competitive edge.

- Optimized Cost Efficiency: Conventional methods incur hidden costs from trial-and-error, including labor, software licensing, material waste, and rework due to poor yield. The AI solution dramatically reduces these costs and helps recover up to 10% in yield loss caused by impedance mismatch—delivering substantial economic benefits to customers.

- Technical Achievement & IP Protection: This internal innovation has moved beyond concept. USI has completed internal reviews and filed patents, demonstrating its commitment to turning this technology into a core competitive asset.

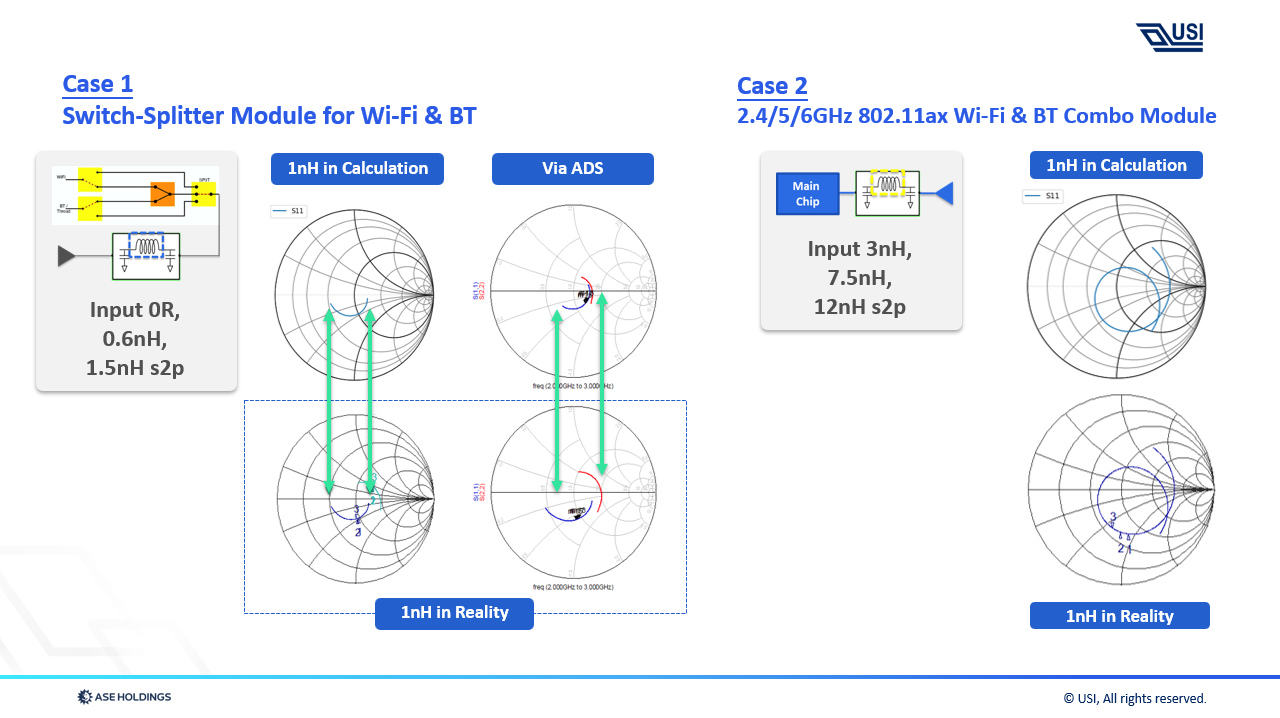

Fig 1. Data Prediction Model – Wi-Fi Module Fitting Example

AI Everywhere: Unlocking Infinite Possibilities

This AI-powered solution is highly versatile and applicable to nearly any project requiring impedance tuning or performance optimization. Industries leveraging RF technologies, such as 5G, Wi-Fi, UWB, automotive electronics, and even medical devices—can benefit from it. It enhances key performance metrics like gain, bandwidth, and noise figure, while also addressing electromagnetic interference (EMI) and compatibility (EMC) challenges to ensure product stability and reliability.

For USI, this innovation marks a milestone. It represents not only a successful internal innovation, but also highlights the company’s continued investment and leadership in advanced R&D. By leading technological innovation, USI continues to create real value for its clients.

Keep up with top trending topic

For the latest innovation technology, application

and industry insight.

Subscribe Our Blog

For the latest innovation technology, application

and industry insight.