Search

- 12/15/2025

Mastering Automotive HPC: Defining the "Sweet Spot" of SoMoG Technology

Speaker: Dr. Li-Cheng Shen, AVP, Miniaturization Competence Center (MCC) of UG

This year (2025), Dr. Li Cheng Shen of UG was invited to be the keynote speaker at the IMPACT 2025, during which Dr. Shen also delivered a keynote speech titled "System-on-Module on Glass Core Substrate (SoMoG)" on behalf of the Hi-CHIP Alliance, which includes key industry players such as Unimicron and ITRI, pointing out a key turning point in the automotive industry.

Fig 1. Dr. Shen as the keynote speaker in IMPACT 2025

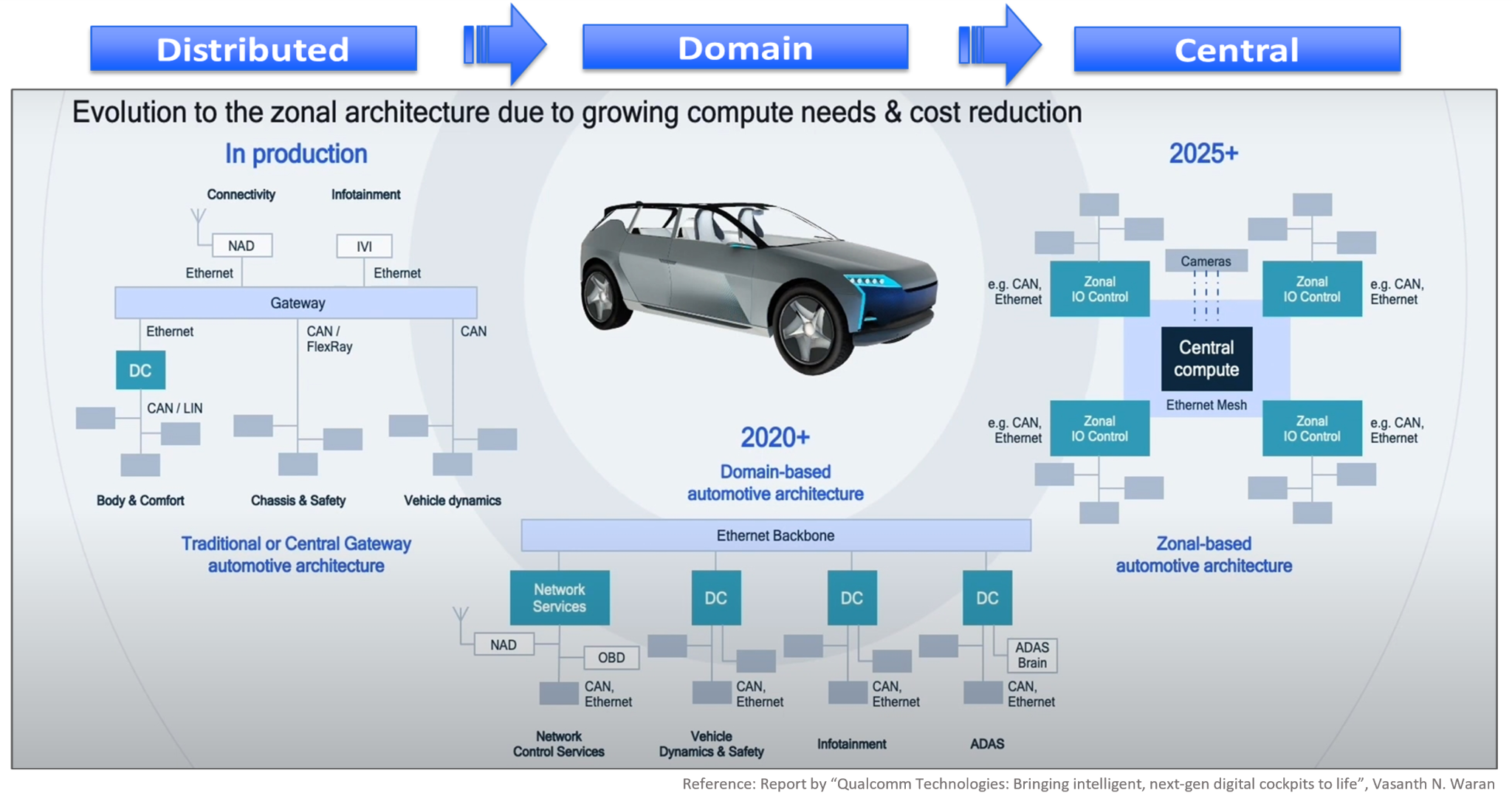

As vehicle architectures migrate from distributed systems to centralized "zonal" computing, cars are evolving into mobile data centers, creating immense pressure on HPC modules regarding size, power, and thermal management. Meanwhile, Dr. Shen presented a rigorous "Apple-to-Apple" comparison demonstrating that Glass-Core Substrates are the answer. This technology is not merely an alternative material but a catalyst for "design freedom," enabling engineers to break traditional compromises between electrical performance and mechanical stability, setting a new standard for next-generation automotive electronics.

Fig 2. Dr. Shen as the keynote speaker in IMPACT 2025

The Paradigm Shift: From Cloud to Edge in Automotive

Dr. Shen contextualized the research within the automotive industry's paradigm shift from distributed architectures to centralized "zonal" computing. As vehicles evolve into "edge data centers" and "mobile clouds," the demand for powerful, cost-effective CPUs is driving HPC modules to become physically larger and more power-hungry. This centralization creates significant electrical, thermal, mechanical, and reliability challenges, leading UG to investigate a pivotal question: "Can we do something better from a glass-core substrate?"

Fig 3. Paradigm Shift of Vehicle Electrical Architecture

Why Glass? The Material Advantage

UG’s interest in glass is driven by specific material properties that address the limitations of organic substrates in the HPC era. Dr. Shen highlighted several critical advantages of glass:

- Electrical Superiority: Glass offers very low dielectric loss and high insulation resistance, which are crucial for high-speed signal integrity.

- Physical Stability: The ultra-smooth surface of glass allows for finer line widths and spacing, while its exceptional dimensional stability supports large-panel processing.

- Tunable CTE: Perhaps the most critical feature highlighted was the Coefficient of Thermal Expansion (CTE). Unlike organic materials, the CTE of glass can be tuned to be compliant with both the silicon die and the PCB motherboard, a flexibility that became the focal point of the mechanical simulation results.

Performance analysis: the trinity of design

Dr. Shen’s presentation was focused on three key performance factors: Electrical, Mechanical, and Thermal.

1. Electrical Performance: Unlocking High Frequencies

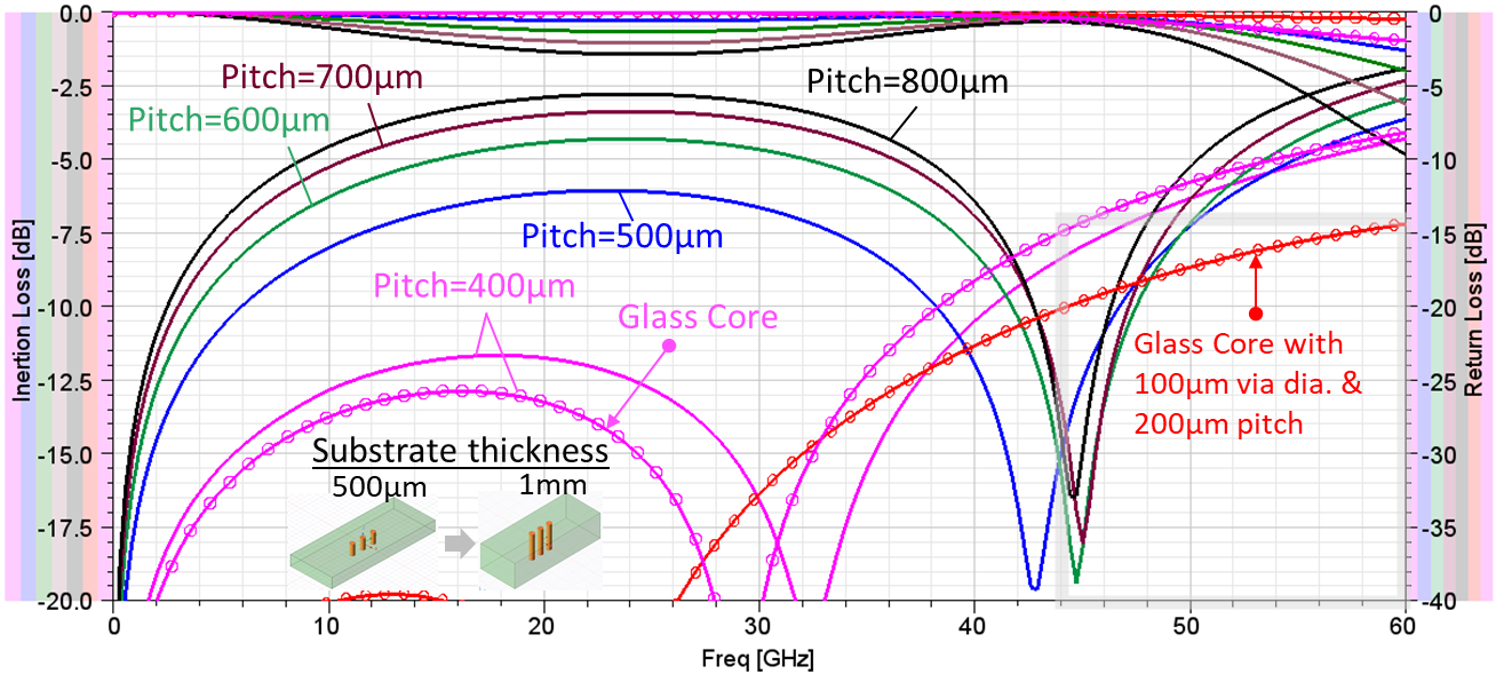

The simulation results for electrical performance were highly promising. The study focused on Through Glass Vias (TGV)—the vertical interconnects within the glass core. Dr. Shen presented data showing that as the TGV pitch is reduced (from 800μm down to 400μm or 200μm), there is a significant improvement in Return Loss. Specifically, the smaller signal return path offered by fine-pitch TGVs leads to better signal integrity.

A fascinating finding was related to core thickness. Typically, in organic substrate, thicker core usually degrades electrical transmission performance. However, it was found that with glass, increasing the core thickness from 500μm to 1mm(while UGng fine-pitch TGVs)actually improved the bandwidth, assuming -15dB return loss as threshold, from 43 GHz up to nearly 60 GHz. This provides engineers with a further degree of design freedom: they can use thicker glass for mechanical rigidity without sacrificing electrical performance.

Fig 4. Electrical Properties: TGV Performance in a 1mm Core

2. Mechanical Performance: The Warpage Surprise

The mechanical simulation section provided the most critical insight for the supply chain. The initial assumption in the industry has often been that because glass has a low CTE (similar to Silicon), it would naturally minimize warpage. However, Dr. Shen revealed that simply swapping organic material for low-CTE glass (3.25 ppm) actually worsened the warpage in the simulation. This is because a System-on-Module is a composite structure containing not just the Silicon die (CTE ~3 ppm), but also molding compounds, copper, and other components with varying expansion rates.

Through a virtual Design of Experiments (DOE), UG simulated various glass CTE values ranging from 3.25 ppm to 13 ppm to see if anything different. A "sweet spot" was found at CTE approximately of 12 ppm. At this range, the warpage was significantly reduced compared to the organic baseline. This finding is impactful for material selection: UG has identified that for module-level integration, the ideal glass core isn't necessarily as small as possible, but the one that balances the entire package stress.

Fig 5. Mechanical Performance: Warpage vs. CTE Optimization

3. Thermal Management: Incremental Gains

Thermal dissipation remains a challenge in HPC. The simulation compared the thermal conductivity of the organic core (approx. 0.58 W/mK) against the glass core (1.2 W/mK). The results showed a consistent thermal improvement with the glass core, reducing the hotspot temperature by approximately 3°C. As noted by Dr. Shen, although this wasn't a "huge" difference, in the world of high-performance computing, every degree counts. Furthermore, the study explored the difference between "conformal" copper plating (Cu plating on the side walls of the via) versus "solid" copper filling (Cu filling the via completely). The solid copper TGV provided further thermal benefits.

The further study from system point of view showed that system-level architecture (such as UGng a high thermal conductivity PCB for the mainboard) had a much larger contribution to reduce temperatures by nearly 20°C. This highlights UG's strength in system-level integration, advising customers not just on the module, but on the entire operating environment.

Fig 6. Thermal Simulation Results (Heat Maps)

The Roadmap: From Simulation to Mass Production

Dr. Shen concluded the deep dive by outlining the roadmap for the SoMoG project. The simulations have successfully validated the design concept, confirming that Glass-Core Substrates can offer superior electrical bandwidth, better thermal dissipation, and if the CTE is tuned correctly, superior mechanical stability. The "System on Module on Glass-Core Substrate" presentation at IMPACT 2025 was a demonstration of UG’s capability and key advantages to its clients and the global supply chain:

- Design Freedom & Flexibility: UG has proven that it does not need to compromise between electrical performance and mechanical reliability. By leveraging the tunable CTE of glass and fine-pitch TGVs, UG can design modules that are both electrically faster and mechanically flatter than current organic solutions.

- System-Level Optimization: UG moves beyond simple assembly. The insights into thermal management (advising on motherboard PCB materials) and warpage simulation (advising glass suppliers on optimal CTE) demonstrate that UG acts as a true technical consultant and solution provider.

- Advanced Process Capability: The transition to glass requires handling new materials, laser processes, and metal-to-metal (M2M) bonding techniques. UG’s active leadership in the Hi-CHIP consortium ensures it is at the forefront of establishing these manufacturing standards.

From Concept to Reality: The Hi-CHIP Blueprint

In summary, as the automotive industry races toward centralized high-performance computing, UG is positioning itself not just as a manufacturer, but as a critical development partner capable of managing the complex material physics required to build the next generation of smart vehicles. For automotive OEMs and chipmakers looking to overcome the thermal and signal integrity bottlenecks of current organic substrates, UG’s SoMoG platform offers a validated, data-backed path forward. We invite partners to engage with our Miniaturization Competence Center to explore how these glass-core technologies can be adapted for your specific next-generation vehicle architectures.

Keep up with top trending topic

For the latest innovation technology, application

and industry insight.

Subscribe Our Blog

For the latest innovation technology, application

and industry insight.