Search

- 08/22/2022

How to develop a more Sustainable Supply Chain?

The one thing trending about supply chain is sustainable supply chain management. Balancing costs and streamlining business processes are essential to creating resilient and efficient logistics and supply chain management. The Supply chain base on green strategies became an emerging initiative to optimize the global supply chain better in recent years. Creating a better supply chain isn’t just the better thing to do; it is also financially more rewarding for the business.

What is sustainable supply chain management? How to create it?

Sustainable supply chain management is the implementation of eco-friendly methods into the traditional supply chain to minimize carbon footprints and waste while maximizing efficiency. A conventional supply chain may be modified into green by including the “environment” factor in each level of the supply chain – from product development to production to distribution to end customers, which may be achieved by developing applicable policies.

For instance, in packaging materials, a number of the packaging are reached with boxes made from plastic. Businesses should work on minimizing using plastic and transferring to packaging crafted from sustainable materials to assist in the reduction of plastic in addition to raising green materials. Another way for brand owners of turning your supply chain sustainable may be to have a fantastic return policy. You can refurbish and recycle the products which have been returned to assist in waste reduction additionally.

What are the benefits of a Sustainable Supply Chain?

Apart from impacting the surroundings definitely, a supply chain adopting sustainable practices has lots of advantages for a business:

- Cost Reduction

Companies can save costs by enforcing digital technology that assists in going energy conservation. IT Solutions that help in low energy consumption, substituting energy sources, and recycling can positively affect a business financially in a positive way. While enforcing green initiatives, companies recognition on lowering greenhouse gas emissions, leading to shorter trips and decreased shipments; this reduces costs as vehicles use much less fuel and go through minimized wear and tear.

- Building Brand Goodwill and Gaining Competitive Advantage

With facts comfortably available online, having a sustainable supply chain will assist you in building your brand reputation. Businesses that increase environment-friendly and technologically superior merchandise could be capable of creating and preserving their brand image. Customers want to shop from environmentally accountable companies, and going green is an outstanding manner to allow them to understand that your enterprise has embraced the sustainable revolution.

- Sustainability of Resources

If a business has carried out sustainable practices in its supply chain, there must be a process or policy in the supply chain that allows them to recycle at the same tempo at which its product is consumed.

As the global pace of international investments, trade, and supply chain is slowing down, a rapid shift in manufacturing industry is seen from global to local facilities, which further helps ease production and delivery of the same. When resorting to local facilities helps us lower the cost of raw materials as the cost of fuel is reduced substantially. Purchasing raw materials locally boosts the local economy as well.

To conform to the supply chain strategy of “global demand and localized service”, USI has 27 manufacturing and service sites in 10 countries and regions worldwide. The global landscape enables us to fully meet the needs of European and American customers and have production bases in major low-cost manufacturing regions worldwide, further integrating the global supply chain to enter new end markets.

USI’s Implementation for a more sustainable supply chain

USI fully understands that the right direction of procurement is the key to the right impact in the supply chain. In order to pursue sustainable growth while meeting the needs of our customers, in the Company's daily procurement operations, in addition to cost and quality considerations, we also evaluate the overall sustainable value generated by the supply chain. Meanwhile, USI has actually developed supply chain strategies for developing stable partnerships with suppliers:

- Value-Oriented

- Diversified Sources

- Quality First

- Strategic Cooperation

- Sustainable Sourcing

- Responsible Minerals Sourcing

Based on this strategy, USI has implemented a number of projects that focus on supply chain diversity, sustainable procurement, and packaging savings.

- Implementation in Warehousing Reuse

In cooperation with local suppliers, the Nantou Facility recycled and reused 13,105 plastic pallets and 6,798 wood pallets in 2021, and saved approximately CNY 3.31 million.

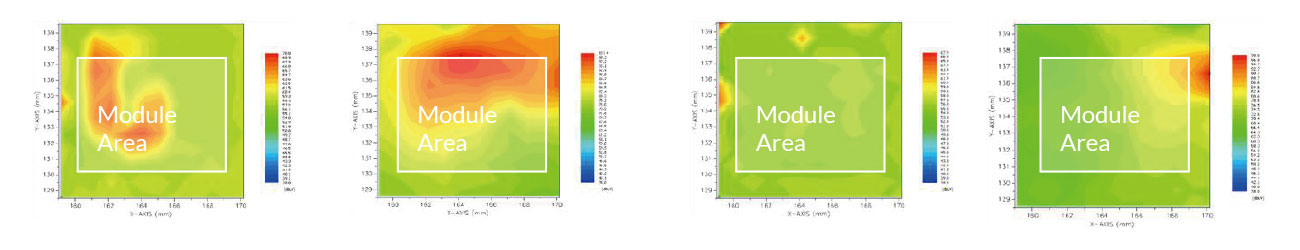

- Implementation in Packaging Recycling

We collaborate with major processing vendors to recycle packaging materials and reduce environmental damage. In 2021, the Nantou Facility recycled a total of 1.13 million trays, 230,000 partitions, and 60,000 recycling bins, a total of 562.66 metric tonnes of waste were reduced and saved approximately CNY 9.14 million.

- Implementation in purchasing

USI supports local suppliers. This strategy not only facilitates the growth of the local economy and increases local employment rates, but also effectively saves energy and time consumed in transportation, helping us to minimize the impact on our environment. Therefore, our raw materials are primarily purchased from local or nearby suppliers.

The procurement situation of local raw material suppliers in 2021 is 43% in Mainland China and an average of 39% of local procurement of integrated manufacturing plants in the global total procurement. Our strategic procurement department will continue to strengthen the management of target suppliers and select local vendors with competitive advantages. We will continue aim to maintain a local procurement rate of at least 35% worldwide in 2026.

The Pressing Needs of the sustainable supply chain

The need for sustainable and responsible business practices becomes more important as our world becomes increasingly connected. USI has realized that sustainability is essential to the long-term success of our business. We are therefore committed to continuously improving our environmental and social performance and aim to reduce our ecological footprint, increase resource efficiency, and promote sustainable development.

Through continuous practical actions and management in supply chain, USI has devoted ourselves to reducing environmental impact and supporting the social and economic development of the communities in which we operate. We strive to develop and maintain strong relationships with our suppliers within the entire industry chain to achieve mutual prosperity together. It based on mutual trust and respect while believing that by working together, we can positively impact society and create a brighter future for us all.

Keep up with top trending topic

For the latest innovation technology, application

and industry insight.

Subscribe Our Blog

For the latest innovation technology, application

and industry insight.