Search

- 02/13/2023

What you should not miss about IGBT and SiC in EV Power Module

Early in 2020, the Pandemic had a limited impact on the EV industry because of lockdowns. The need for EVs charging stations increased in 2021 because of the rising demand for EVs during the Pandemic and global government incentives. Over the past three years, leading EVs manufacturers have quickly increased their EVs sales.

The trend for low-cost, low-emission vehicles is expected to drive steady expansion in the EV market throughout Asia Pacific, while rising government initiatives and the expanding market for high-performance vehicles are driving rapid growth in North America and Europe. Therefore, it is anticipated that 39208 thousand EVs will be sold globally in 2030. At a predicted CAGR of 21.7%, the size of the global electric vehicle market is expected to increase from 8151 thousand units in 2022 to 39208 thousand units by 2030.

Moderate control modules should be chosen wisely in electric vehicles. It is in charge of most operations about how electrical or hybrid-electric vehicles function. Which were widely recommended worldwide in industry, no doubt would be the IGBT and SiC modules. SiC module was first used by Tesla and is now used by other manufacturers in their power inverters.

What are IGBT modules, and how does it Work?

Insulated-gate bipolar transistors, sometimes IGBTs, are three-terminal power semiconductor devices most frequently utilized as electronic switches. Due to its capacity to improve switching, temperature, weight, and cost performance, IGBT power modules are increasingly used as the preferred technology for high-power applications like electric vehicles. An IGBT power module performs the role of an electrical switch in Vehicles. Direct current (DC) can be changed into alternating current (AC) and vice versa by alternative switching.

And why is everyone talking about SiC modules?

Combining silicon (Si) and carbon (C), silicon carbide has distinct electrical properties that make it possible to create solid semiconductors for various applications. The cost of manufacturing silicon is low, and the technique is well known. It is now scientifically and practically feasible for silicon carbide (SiC) to compete with silicon to manufacture power semiconductors. Compared to Si, SiC is a far more effective electrical conductor. High conversion efficiency electrical power, which results from current and voltage, is transformed using a SiC power module. It is becoming more widely known that the 600–1,700V range of SiC power devices on the market provides a quick switching substitute for conventional silicon (Si) power devices.

Due to SiC power semiconductors' essential efficiency properties, which enable cost savings while simultaneously boosting system performance in several applications such as xEV chargers, solar converters, e-mobility, and power electronics, it is anticipated that their use will increase dramatically.

Why do IGBT and SiC play such essential roles in EV performance?

A battery-powered electric vehicle (BEV) has a conversion efficiency of 59%–62%, which appears to have considerable room for improvement. Still, there is a potential roadmap for improved performance from EVs with new switching devices that can be used in the drivetrain.

According to Mordor Intelligence, the IGBT market was valued at USD 6.047 billion in 2020 and is expected to reach USD 11.01 billion by 2026. Another reason for the growth of IGBTs is the electrification of the automotive powertrains in electric and hybrid vehicles (EV/HEV). With IGBTs, conduction and switching losses are significantly reduced, thus directly impacting the vehicle's overall efficiency. Sales of electric cars in Europe, North America, and China are creating new avenues for IGBTs to support infrastructure and manufacturing EVs. These sales help further strengthen the stance of IGBT in the marketplace.

As more Wide bandgap (WBG) materials are being used in electric vehicles and other forms of power conversion, the latest-generation SiC module can offer better conditions for the EV. It might be the most suitable candidate for EVs at high temperatures and under repeated stress to improve efficiency and faster switching rates, generating substantial cost, size, and energy savings.

- More than 50% module/package size reduction.

- 70% lower loss at full load and much lower loss at low load allows smaller battery for the same range.

- 40% cooling system downsize, which lower losses at full load, giving a smaller cooling system

- Giving better reliability in the whole load range

IGBT & SiC, USI is ready to provide you BOTH

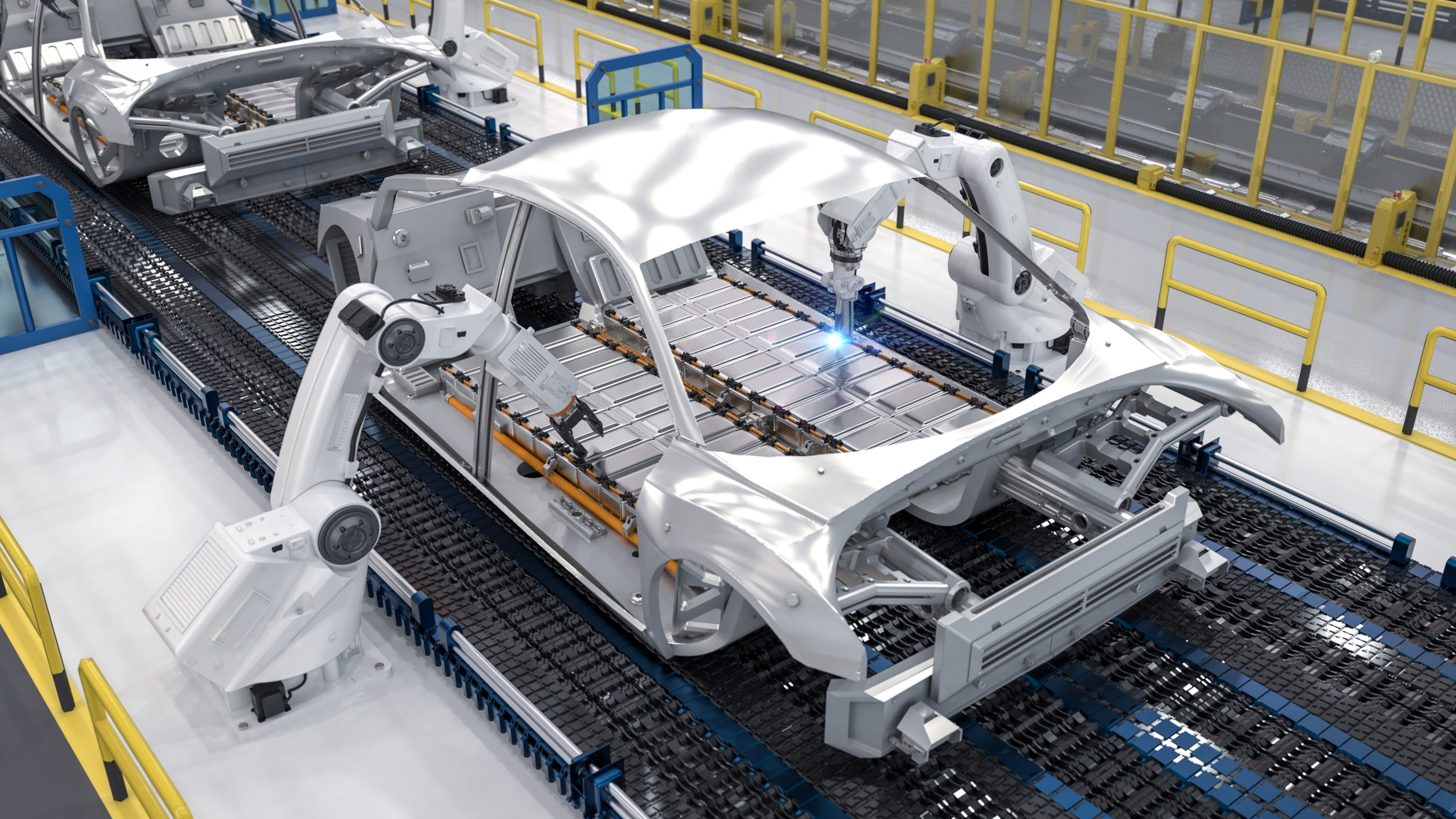

USI has more than 40 years of experience in the automotive electronics field. With a flexible and agile structure, USI will introduce product automation to continuously improve powertrain manufacturing and testing technology related to electric vehicles.

Furthermore, in recent years, we have begun laying out the assembly and testing of power modules for major international power semiconductor suppliers from Europe, USA, and Japan. As a result, USI has already put IGBT modules for electric vehicle inverters into mass-produce in 2022 and expects to launch the SiC in 2023 officially.

With the rapid growth of the electric vehicle market, USI is bringing customers top-notch automotive solutions. The following five years will continue to grow, bringing a tremendous boost to the automotive electronics business. Whether a customer needs an IGBT or a SiC module, USI is prepared to meet your needs with the newest technology and various configurations.

Keep up with top trending topic

For the latest innovation technology, application

and industry insight.

Subscribe Our Blog

For the latest innovation technology, application

and industry insight.