Search

- 05/21/2024

【MFG in USI】AMHS : Invisible Hands in Light-off Factory

The landscape of manufacturing is undergoing a radical transformation. With Industry 4.0 taking center stage, automation and intelligent systems are no longer futuristic concepts – they are the cornerstones of success. Industry 4.0 revolutionizes manufacturing with smart management technologies like AMHS.

Smart factories, powered by AMHS and smart manufacturing technologies, are revolutionizing manufacturing operations, paving the way for a more dynamic manufacturing future. In this dynamic environment, USI, a leading electronics manufacturing service (EMS) provider, is at the forefront of innovation, leveraging AMHS to unlock the full potential of our light-off factory vision.

Understanding AMHS: The Backbone of Smart Manufacturing

Industrial smart solutions like AMHS transform factories into interconnected ecosystems, optimizing smart production from start to finish. As the core of smart manufacturing and Industry 4.0, AMHS is an intricate network of automated equipment and software that orchestrates the seamless flow of materials within a manufacturing facility.

This encompasses a range of technologies, including robotic systems, conveyor belts, and intelligent vehicles, all working in concert to streamline processes and enhance efficiency. AMHS plays a pivotal role in smart manufacturing and Industry 4.0 by transforming factories into intelligent ecosystems. By automating material handling tasks, AMHS minimizes human intervention, leading to:

USI's light-off factory vision is committed to intelligent and sustainable manufacturing practices. By implementing AMHS, USI aims to create a lights-out production environment, minimizing human presence on the factory floor while maximizing efficiency and environmental responsibility through smart manufacturing technologies.

Learn More: 4 Essentials in Industrial 4.0 you should keep an eye on

The Key Components of Smart Factory: The Symphony of Industry 4.0 Automation

Smart manufacturing technologies combined with AMHS allowing for flexible production adjustments based on real-time data. For the entire smart factory to operate in a coordinated manner, the core of the focus must accurately grasp each link and have the ability to calculate a large amount of data; therefore, having a strong "control center" will be the biggest key to the smooth operation of the smart factory, a cornerstone of Industry 4.0. Then, through the Industrial Internet of Things (IoT) and the cloud, all the devices are connected to achieve real-time execution of tasks in this smart manufacturing ecosystem.

In USI's Lights Out Factory, a prime example of smart factory 4.0, the five most important components include the Control Room, the Work-in-Process (WIP) Warehouse, the Automated Material Handling System(AMHS), the Testing Common Platform, and the Warehouse Management System(WMS), which is driven by big data.

A. Control Room

B. Work-in-Product (WIP) Warehouse

C. Real-Time Consumption Monitoring by AI Computing

D. AMHS & AGV with Auto Dispatching

E. Testing Common Platform

F. Data-Driven WMS

By creating a foundation for smart production through optimized material dispatching flow and industrial smart automation supply chain, AMHS start to become a cornerstone of smart factories. Modern AMHS are not just about automation; they are also about harnessing the power of data for dynamic manufacturing. Sensors and software collect real-time data on material flow, equipment performance, and inventory levels. AI analyzes this data to optimize processes, predict potential issues, and make data-driven decisions for continuous improvement in smart production.

Learn More: Smart Manufacturing: How can smart manufacturing help you thrive and make the next 'smart' move?

Meanwhile, through the Industrial Internet of Things (IIoT), equipment monitoring, warehouse management system (WMS), warehouse control system (WCS) and manufacturing execution system (MES) are connected, the whole system can monitor the problems in production in real-time. This smart factory solution enables the equipment failure warning to send messages to the management staff in advance. Through big data, the overall equipment efficiency (OEE) has been improved by more than 20%, and the time to analyze problems has been reduced by 95%.

Giant Leap in USI by Applying Smart Factory & AMHS

A. Cost Effectiveness Improvements

Future Blueprint in USI Light-off Manufacturing

High tech Industries are significantly shifting towards smart production with the adoption of AMHS and other smart manufacturing technologies. Adapting with smart manufacturing technologies is crucial for manufacturers to prepare for the future of smart production. USI's AMHS journey is far from over. As they continue to refine their implementation, we can expect to see further advancements such as:

Building a Supportive, Intelligent Workforce

While AMHS automates many tasks, human expertise remains essential. Manufacturers must invest in training programs that equip their workforce with the skills to operate, maintain, and continuously improve Industry 4.0 AMHS systems.

Expanding Artificial Intelligence (AI) Input

AI can not only play a crucial role in optimizing AMHS by enabling predictive maintenance real-time process adjustments, but also even autonomous decision-making for material handling tasks. Therefore, USI continues to strengthen its AI computing core, and future projects include enhanced machine vision sensing capabilities, accelerated computing power in Industry 4.0 (I4.0 industrial) control systems, and expanding the scope of automated monitoring and management.

Collaborative Robotics (Cobot) for more Highly Efficiency

The future of AMHS likely involves increased collaboration between humans and robots. Cobots, designed for safe interaction with humans, can take on tasks that require dexterity or human judgment, while robots handle heavy lifting and repetitive tasks.

By embracing Automated Material Handling Systems (AMHS) and continuously innovating, USI is setting the stage for a future of intelligent and sustainable manufacturing. Our vision includes achieving 80%- 100% automation, 100% equipment interconnection, and a 70% improvement in both direct and indirect labor efficiency—all contributing to optimized manufacturing costs80%-100% automation, 100% equipment interconnection, and a 70% improvement in both direct and indirect labor efficiency – all contributing to optimized manufacturing costs.

The successful implementation of AMHS exemplifies its critical role in the Smart Manufacturing Factory space. By integrating equipment networking, big data analysis, and AI real-time computing, the entire smart factory can operate in a coordinated manner. This allows USI to achieve targets and attract customer orders by showcasing their automated production capabilities at each site. It positions us at the forefront of the industry, ready to embrace the new era of smart manufacturing!

Smart factories, powered by AMHS and smart manufacturing technologies, are revolutionizing manufacturing operations, paving the way for a more dynamic manufacturing future. In this dynamic environment, USI, a leading electronics manufacturing service (EMS) provider, is at the forefront of innovation, leveraging AMHS to unlock the full potential of our light-off factory vision.

Understanding AMHS: The Backbone of Smart Manufacturing

Industrial smart solutions like AMHS transform factories into interconnected ecosystems, optimizing smart production from start to finish. As the core of smart manufacturing and Industry 4.0, AMHS is an intricate network of automated equipment and software that orchestrates the seamless flow of materials within a manufacturing facility.

This encompasses a range of technologies, including robotic systems, conveyor belts, and intelligent vehicles, all working in concert to streamline processes and enhance efficiency. AMHS plays a pivotal role in smart manufacturing and Industry 4.0 by transforming factories into intelligent ecosystems. By automating material handling tasks, AMHS minimizes human intervention, leading to:

- Reduced errors: Repetitive tasks are prone to human error. AMHS eliminates this risk, ensuring consistent and accurate material handling.

- Increased productivity: Automated systems operate tirelessly, significantly boosting production output.

- Enhanced flexibility: AMHS can be programmed to adapt to changing production requirements, facilitating more agile manufacturing operations Process.

USI's light-off factory vision is committed to intelligent and sustainable manufacturing practices. By implementing AMHS, USI aims to create a lights-out production environment, minimizing human presence on the factory floor while maximizing efficiency and environmental responsibility through smart manufacturing technologies.

Learn More: 4 Essentials in Industrial 4.0 you should keep an eye on

The Key Components of Smart Factory: The Symphony of Industry 4.0 Automation

Smart manufacturing technologies combined with AMHS allowing for flexible production adjustments based on real-time data. For the entire smart factory to operate in a coordinated manner, the core of the focus must accurately grasp each link and have the ability to calculate a large amount of data; therefore, having a strong "control center" will be the biggest key to the smooth operation of the smart factory, a cornerstone of Industry 4.0. Then, through the Industrial Internet of Things (IoT) and the cloud, all the devices are connected to achieve real-time execution of tasks in this smart manufacturing ecosystem.

In USI's Lights Out Factory, a prime example of smart factory 4.0, the five most important components include the Control Room, the Work-in-Process (WIP) Warehouse, the Automated Material Handling System(AMHS), the Testing Common Platform, and the Warehouse Management System(WMS), which is driven by big data.

A. Control Room

USI Real-time Production Monitoring System

B. Work-in-Product (WIP) Warehouse

C. Real-Time Consumption Monitoring by AI Computing

Automated Material Handling Systems (AMHS)

D. AMHS & AGV with Auto Dispatching

USI Autonomous Guided Vehicles (AGV)

E. Testing Common Platform

USI Fully Automated Testing Station

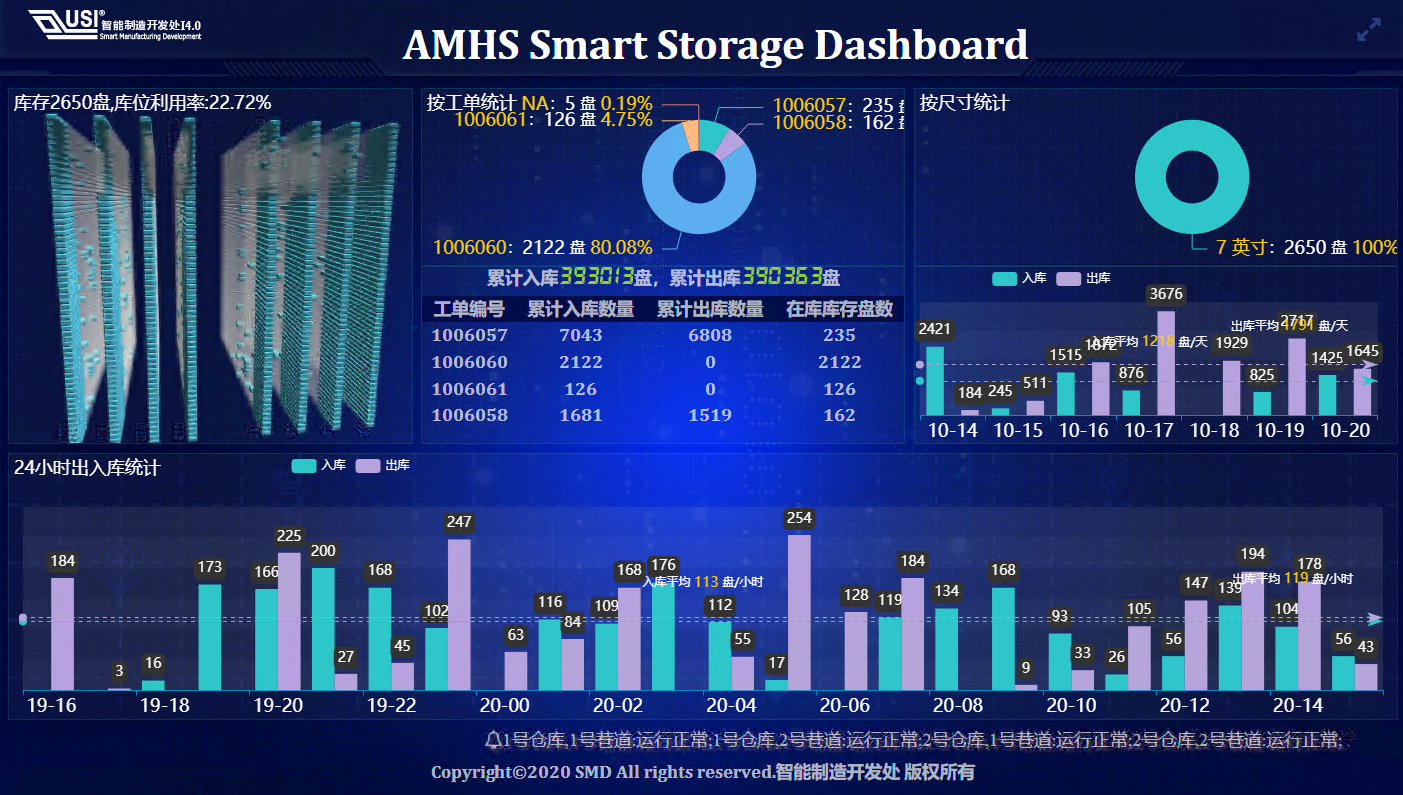

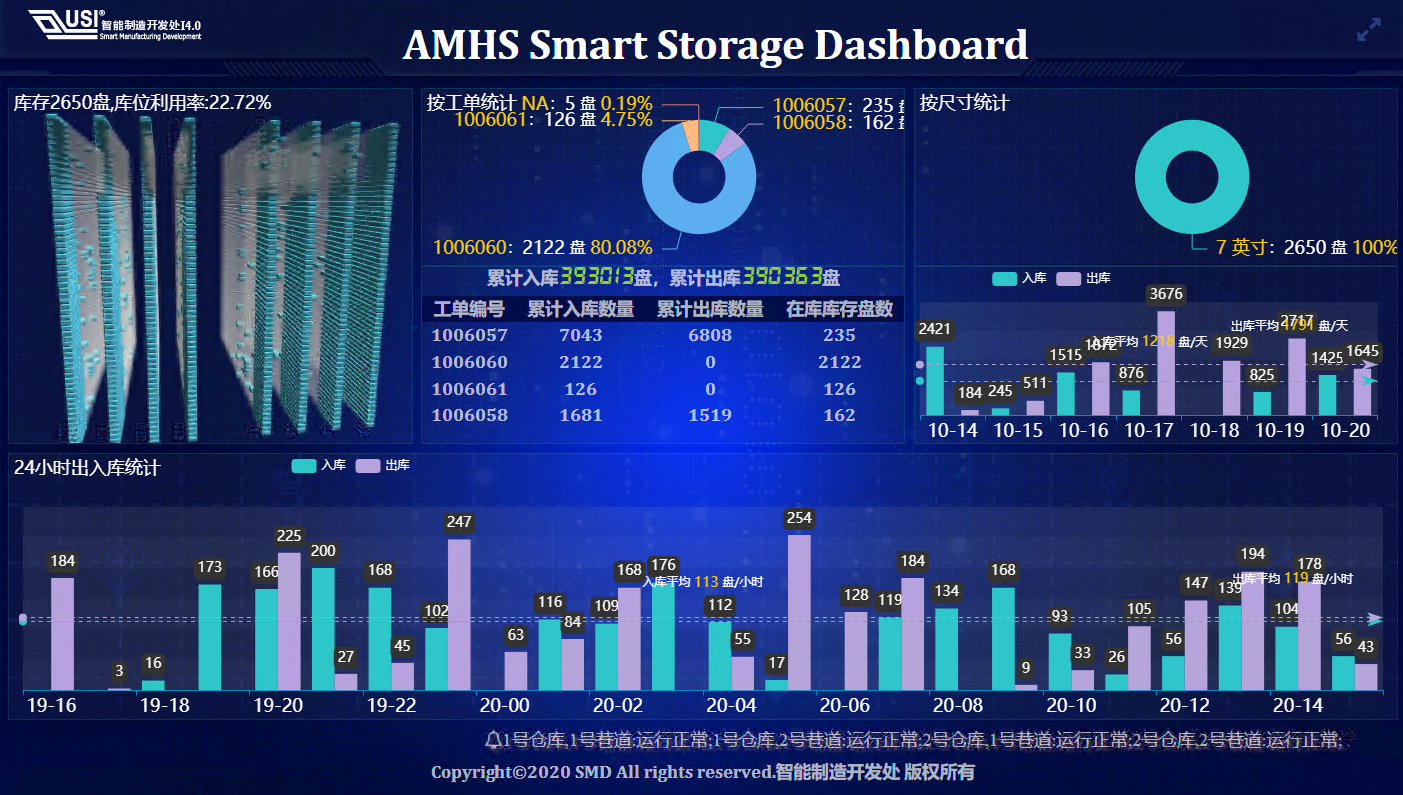

F. Data-Driven WMS

By creating a foundation for smart production through optimized material dispatching flow and industrial smart automation supply chain, AMHS start to become a cornerstone of smart factories. Modern AMHS are not just about automation; they are also about harnessing the power of data for dynamic manufacturing. Sensors and software collect real-time data on material flow, equipment performance, and inventory levels. AI analyzes this data to optimize processes, predict potential issues, and make data-driven decisions for continuous improvement in smart production.

Learn More: Smart Manufacturing: How can smart manufacturing help you thrive and make the next 'smart' move?

Meanwhile, through the Industrial Internet of Things (IIoT), equipment monitoring, warehouse management system (WMS), warehouse control system (WCS) and manufacturing execution system (MES) are connected, the whole system can monitor the problems in production in real-time. This smart factory solution enables the equipment failure warning to send messages to the management staff in advance. Through big data, the overall equipment efficiency (OEE) has been improved by more than 20%, and the time to analyze problems has been reduced by 95%.

Giant Leap in USI by Applying Smart Factory & AMHS

A. Cost Effectiveness Improvements

- Introducing AI-powered inspection capabilities: By implementing AI-powered inspection, the company has achieved an over 90% reduction in defect escape rate, resulting in annual cost savings of RMB$260k.

- Overall production efficiency has doubled in the past three years: The company has implemented a comprehensive range of initiatives that have doubled overall Manufacturing Production efficiency and improved quality loss by over 20%, saving management expenses of over RMB$70M.

- USI's smart warehouse: The company's smart warehouse integrates a warehouse management system (WMS), autonomous guided vehicles (AGVs), a dispatching and delivery system, and robotic arms to enable just-in-time (JIT) production. The dispatching system manages Logistics between stations, coordinating AGVs and robotic arms to transport semi-finished goods (WIP), minimizing WIP inventory. This approach optimizes factory space utilization and paves the way for unmanned operations, aligning with the goals of Industry 4.0.

- Real-time data analysis and in-line SPC: The company's Industry 4.0 system analyzes vast amounts of production quality data and implements in-line statistical process control (SPC) to provide production line supervisors with real-time insights and enable them to take prompt action. This significantly reduces lead times, improves overall equipment efficiency (OEE), and enhances production yield.

- Highly integrated Light-Out Factory: USI's Light-off factory currently operates with hundreds of robotic arms, AGV, and a smart warehouse. All systems are highly integrated, and Light-off factory planning is considered from the design stage. Data from all robotic arms and test fixtures is networked through the I4.0 EAP system, enabling real-time analysis of the mean time between failures (MTBF) and OEE. This data is further utilized to support continuous improvement initiatives.

- AI-assisted anomaly detection and resolution: The I4.0 system can automatically detect and resolve anomalies in the Light-off factory or remotely through the control room. AI capabilities also assist management personnel in automatically identifying anomalies, and all alert messages are sent to management personnel's communication devices, truly achieving the goal of labor savings.

Future Blueprint in USI Light-off Manufacturing

High tech Industries are significantly shifting towards smart production with the adoption of AMHS and other smart manufacturing technologies. Adapting with smart manufacturing technologies is crucial for manufacturers to prepare for the future of smart production. USI's AMHS journey is far from over. As they continue to refine their implementation, we can expect to see further advancements such as:

Building a Supportive, Intelligent Workforce

While AMHS automates many tasks, human expertise remains essential. Manufacturers must invest in training programs that equip their workforce with the skills to operate, maintain, and continuously improve Industry 4.0 AMHS systems.

Expanding Artificial Intelligence (AI) Input

AI can not only play a crucial role in optimizing AMHS by enabling predictive maintenance real-time process adjustments, but also even autonomous decision-making for material handling tasks. Therefore, USI continues to strengthen its AI computing core, and future projects include enhanced machine vision sensing capabilities, accelerated computing power in Industry 4.0 (I4.0 industrial) control systems, and expanding the scope of automated monitoring and management.

Collaborative Robotics (Cobot) for more Highly Efficiency

The future of AMHS likely involves increased collaboration between humans and robots. Cobots, designed for safe interaction with humans, can take on tasks that require dexterity or human judgment, while robots handle heavy lifting and repetitive tasks.

By embracing Automated Material Handling Systems (AMHS) and continuously innovating, USI is setting the stage for a future of intelligent and sustainable manufacturing. Our vision includes achieving 80%- 100% automation, 100% equipment interconnection, and a 70% improvement in both direct and indirect labor efficiency—all contributing to optimized manufacturing costs80%-100% automation, 100% equipment interconnection, and a 70% improvement in both direct and indirect labor efficiency – all contributing to optimized manufacturing costs.

The successful implementation of AMHS exemplifies its critical role in the Smart Manufacturing Factory space. By integrating equipment networking, big data analysis, and AI real-time computing, the entire smart factory can operate in a coordinated manner. This allows USI to achieve targets and attract customer orders by showcasing their automated production capabilities at each site. It positions us at the forefront of the industry, ready to embrace the new era of smart manufacturing!

Keep up with top trending topic

For the latest innovation technology, application

and industry insight.

Subscribe Our Blog

For the latest innovation technology, application

and industry insight.